The compressed air system in Pharma

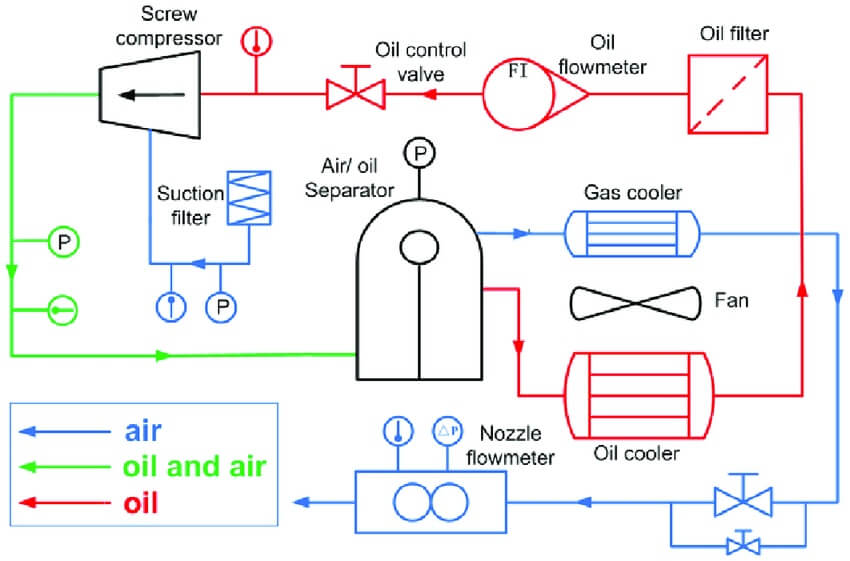

The Moisture free Compressed Air system comprises of state-of-the-art Vertical single cylinder reciprocating air-cooled compressor with a “V” Belt arrangement, starter cum control panel, safety devices, interconnecting piping, cabling, etc. and accessories duly mounted on a rigid steel deck. These packages are provided with anti-vibration mountings to reduce the vibration from being transmitted to the floor hence eliminating elaborate civil foundation.

Static pass box

The following main parts were considered in the design of the compressed air generator:

Main Frame Body:

Totally enclosed, rigid pressure tight made of high-grade, close-grained C. I precision machined and stress relieved for permanent alignment. Two bearings fitted on the drive end side give better support to the crankshaft aided with one bearing fitted on the pump end. Main bearing housing bores are accurately bored to avoid misalignment.

Crank Shaft: High-grade S.G Iron crankshaft and journals duly ground and polished ensure a long life of bearings.

Connecting Rods: Forged alloy steel connecting rod duly normalized is designed to provide minimum thrust on the crosshead bearings surfaces. Big end bearings bores finish machined accommodate prefinished replaceable bearing halves of copper-lead alloy designed for operation. Small end-bearing bushings are of special bronze metal.

Cross Head: should be made lush grade S.G. Iron. Its low inertia along with low friction cross-slides ensures perfect miming of the crosshead. It is hollow design on either side ensures true miming of the piston rod thereby resulting in improved life of packing and maximum life of the piston rod.

Cylinder: Graded C. I cylinders designed with adequate coolant in the jacket ensure optimum heat dissipation of the surfaces in contact with compressed air. Wide jacket doors provided on cylinders ensure easy access for cleaning cylinder jackets. Should be designed for streamlined air passage and a maximum no. of valves Cylinders provide a smooth flow of air thereby minimizing the pressure drop.

Valves: Reduced lift with large flow area, stainless steel, ported plate type valves, both for suction and discharge arranged symmetrically for long life. A protection grill fitted on the suction valve prevents any valve part from failing into the cylinder in case of an accident. Each of the accessibility of these valves of non-reversibility of suction and discharge valves makes it simpler and foolproof for regular maintenance

Oil Pump: Gear-type oil pump directly driven by the crankshaft and fitted on the bearing housing. Therefore, it feeds oil to the main bearings, connected rod bearings and to cross-head slides. A pressure-regulating screw provided on the oil pump body regulates the oil pressure. To increase the pressure regulating screw has to be screwed in and vice versa.

Market Complaint -Stages of Handling

Receiver: MS vertical receiver for storage of compressed air and to drain the moisture content if any. The receiver contains an automatic moisture drain trap and a safety valve for High air pressure in the receiver.

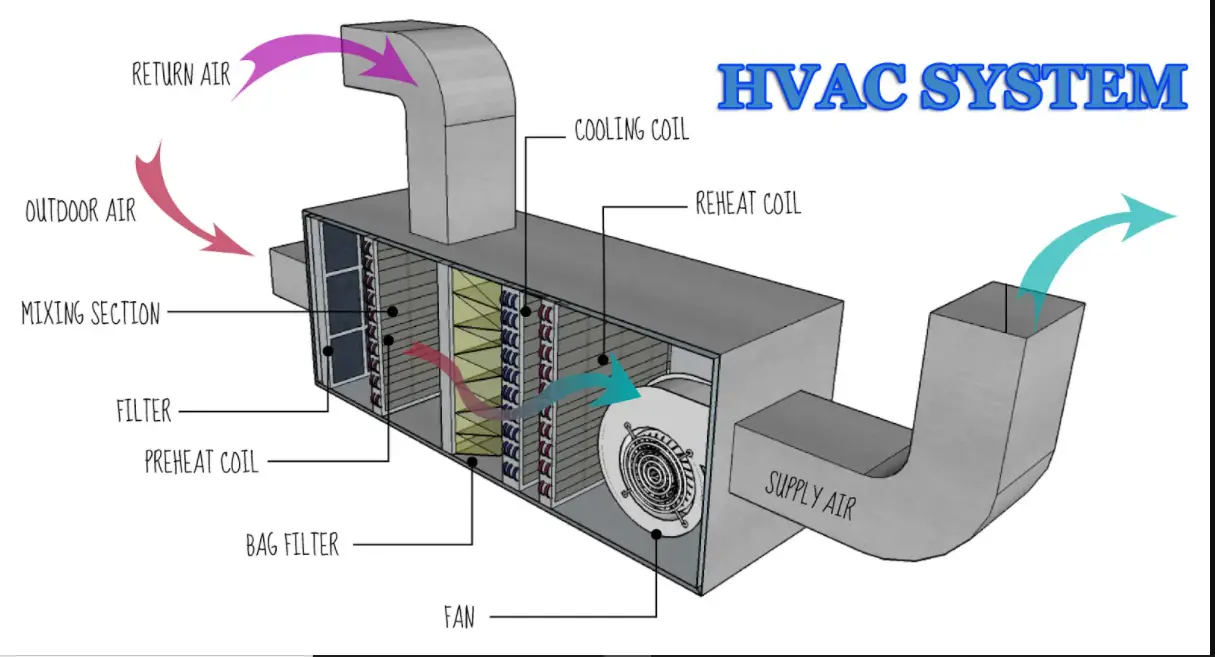

Air dryer: the air entering the system enters the pre-cooler. A pre-cooler is a heat exchanger where the incoming hot air is being cooled by the outgoing cold air to reduce the heat loads for the evaporator and thereby the refrigeration system. Tins are done with the ultimate aim to reduce the refrigeration compressor power. Normally the moisture will be in the water vapor will be condensed. It is easy to remove the moisture as a condensate than the moisture in the water vapor state. For every drop in the temperature of the air. There will be the formation of condensate moisture.

The system has the provision to indicate, and monitor, the parameters of Oil pressure, Air temperature. Discharge air pressure.

The system should have the provision enabling the loading and unloading system depending on the consumption conditions in the process operation.

The system should have the necessary connections for the cooling system, and safety system for the smooth operation of equipment.

Distribution system length: The length of the distribution system plays an important part in deciding the physical quality parameters of the compressed air; hence it is suggested to sample the last User point of the distribution loop as that would simulate the worst-case scenario. Therefore, the user point at receiving Bay Hall has been selected for testing. In addition, the quality of the air generated by the compressor before passing through distribution lines also needs to first qualify on all the parameters, hence the initial point after generation has also been considered in the Sampling plan.

Diclofenac Potassium 50 mg and Serratiopeptidase 10 mg Tablets and its Mechanism of action

Acceptance Criteria:

| Sr. No. | Test | Acceptance Criteria | |||

| 1. | Dew Point* | NMT -40°C | |||

| 2. | Vapor/Moisture content** | ppm | Mg/m3 | ||

| ≤67 | 49.38 | ||||

| 3. | Oil Mist Content* | < 0.1 mg/ m3 | |||

| 4. | Carbon Monoxide Content* | NMT 5 ppm | |||

| 5. | Carbon Dioxide* | NMT 500 ppm | |||

| 6. | Nitrogen Oxide Content* | NMT 2 ppm | |||

| 7. | Sulfur Dioxide Content* | NMT 1 ppm | |||

| 8. | Non-Viable Particle Count Test* | Maximum number of particles per m3 | |||

| 0.1 to 0.5 µ | 0.5 to 1.0 µ | 1.0 To 5.0µ | |||

| ≤ 400000 | ≤ 6000 | ≤100 | |||

| 9. | Hydrocarbon Test# | NMT 1 ppm | |||

| 10. | Oxygen Content | 19.5-23.5% | |||

| 11. | Viable Particle Count Test | As per IP, BP &USP | |||

Revalidation Frequency: Yearly ±1 months

Reference: ISO 8573 guideline