SOP of Viable Particulate Monitoring – MLT Testing and Other Areas – Microbiology

Objective

To lay down the procedure for Viable Particulate Monitoring – MLT Testing and Other Areas – Microbiology.

Scope

This SOP is applicable for Viable Particulate Monitoring in MLT Testing and Other Areas of Microbiology lab (Pharmaceutical Company Name).

Responsibility

Chemist or above of Microbiology Laboratory.

Head – Microbiology Section.

Accountability

Head – Quality Control.

Head – Quality Assurance.

Abbreviations and Definitions

SOP : Standard operating procedure

No. : Number

QC : Quality Control

QA : Quality Assurance

Procedure

Viable particle monitoring in MLT Testing and Other Areas shall be performed by microbiologist, to ensure that the environmental conditions are in compliance with respect to the acceptable levels of total viable count.

Perform the viable particle monitoring in MLT testing and sub-culturing areas by following methods and frequency.

Settle Plates (Passive air sampling) —– Daily and once in a week if there is no activity.

Volumetric Air Sampling (Active air sampling by sieve impaction method) –Weekly once.

Perform the viable particle monitoring in sterilization, media preparation and other areas by Settle Plate once in a week.

Preparation of plates and other accessories:

Prepare and sterilize required number of SCDA (Soyabean Casein Digest agar Medium) plates / cassettes and pre-incubate as per SOP on sterile media preparation (SOP No. :).

Sterilize required number of SS carriers required to carry plates / cassettes.

Disinfect the outer surfaces of the medium plates / cassettes with 1% Protasan DS / 1% Combatan / 1% Triple 100 and place them in the sterile SS carriers.

Carry the plates to the area to be monitored.

Take out the plates from the SS bin and start the monitoring using the procedures mentioned below.

Also read :SOP on Viable Particulate Monitoring – Sterility Testing Area – Microbiology

Settle Plates exposure (Passive air sampling):

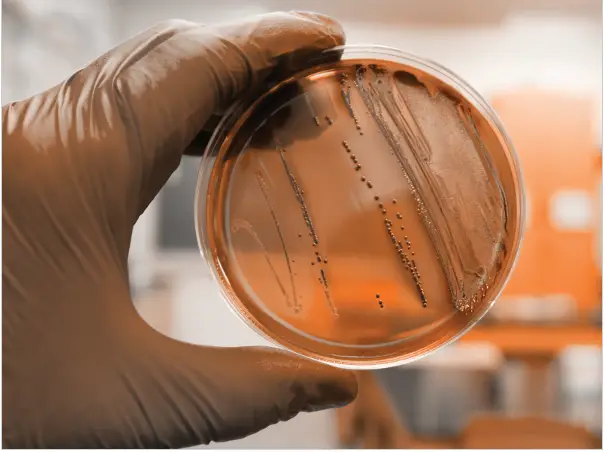

Expose the agar medium plates in the specified area according to the pre-defined locations and settle plate exposure schematic diagrams mentioned in the annexure.

Exposure method.

Bring each plate to the pre-defined locations.

Open the lid of plate carefully.

Place the plate containing medium in the location. Place the plate on the settle plate exposure stand if it is provided for that location.

Place the lid beside this plate internal side down.

Expose the plate for 4 hours.

After completion of exposure time, close the medium plate with lid carefully.

Label each plate on bottom side with location code, date of exposure, media Lot No, and date of media preparation.

Place all the plates in SS carriers.

Perform the monitoring by settle plates under dynamic conditions if activity is there or once in a week if there is no activity.

Volumetric Air Sampling (Active air sampling by sieve impaction method):

Perform the volumetric air sampling in the area (1000 litres / Location) as per the pre-defined locations and volumetric air sampling schematic diagrams mentioned in the annexure.

Perform Air sampling with sieve impaction Air Sampler, as per SOP On Operation, Calibration, Cleaning and Maintenance of M Air T Air Sampler (SOP No.:).

Disinfect the sieve after sampling of every location.

Perform the volumetric air sampling starting from high clean area location to low clean area location sequentially.

After completion of volumetric air sampling, label each plate on bottom side with location code, shift, sign (initial) and date.

Place all the plates in SS carriers.

Perform the monitoring by volumetric air sampling under dynamic conditions once in a week.

Bring all the plates / cassette carriers to incubators room for incubation.

Incubation:

Incubate all plates / cassettes of environmental monitoring and personnel monitoring test at 20-25 0C for 72 hours and at 30-35 0C for further 48 hours. Observe the plates / cassettes after 72 hours and after further 48 hours and record the results in respective report given as annexures.

Documentation

Record the test details of settling plate exposure for MLT testing and sub-culturing area in the report given as Annexure No.: (Format No. :).

Record the test details of Volumetric Air sampling for MLT testing and sub-culturing area and in the report given as Annexure No. 🙁 Format No. :).

Record the test details of settling plate exposure for sterilization, media preparation and other areas in the report given as Annexure No.: (Format No. :).

Acceptable levels:

Verify that the monitoring results are within the acceptable levels mentioned in the particular annexure.

Forms and Records (Annexures)

Report of Viable Particles Monitoring by Settle Plate Method-MLT areas

Report of Viable Particles Monitoring by Volumetric Air Sampling-MLT areas

Report of Viable Particles Monitoring by Settle Plate Method-Other areas.

Distribution

Master copy – Quality Assurance

Controlled copies – Quality Assurance, Production, Quality Control, Stores, Engineering and Human Resource

History:

| Date | Revision Number |

Reason for Revision |

| 00 | NEW SOP |