SOP on Viable Particulate Monitoring – Sterility Testing Area – Microbiology

Objective – To lay down the procedure for Viable Particulate Monitoring – Sterility Testing Area – Microbiology.

Scope –This SOP is applicable for Viable Particulate Monitoring in the Sterility Testing Area of the Microbiology lab.

Responsibility- Chemist or above of Microbiology Laboratory.

Accountability – Head – Microbiologist.

Abbreviations and Definitions

RODAC: Replicate Organism Detecting and Counting

MLT: Microbial Limit Test

LAF: Laminar Air Flow

Procedure:

Viable particle monitoring in the sterility testing facility shall be performed by a microbiologist, to ensure that the environmental conditions of the sterility testing area comply with the acceptable levels of the total viable count.

Perform the viable particle monitoring in the Sterility testing area by following methods.

- Settle Plates (Passive air sampling).

- Volumetric Air Sampling (Active air sampling by sieve impaction method).

- Surface Monitoring by Swabs and 55 mm Surface contact (RODAC) plates.

- Personnel Monitoring 55 mm Surface contact (RODAC) plates.

Preparation of plates and other accessories:

Prepare and sterilize the required number of SCDA (Soya bean Casein Digest agar Medium) plates/cassettes and pre-incubate as per the SOP on sterile media preparation (SOP No.)

Sterilize the required number of tubes containing 10 ml of saline and a swab and place them in the test tube stand.

-Negative cells stain pink color.

Sterilize the required number of SS carriers required to carry plates/cassettes and other accessories.

Place the preincubated media plates/cassettes under the LAF working zone.

Disinfect the outer surfaces of the medium plates/cassettes with 1% Protasan DS / 1% Combatan / 1% Triple 100 and place them in the sterile SS carriers. Place the swab tube stands in the carriers.

Carry the plates to the sterilization area.

Disinfect the outer surfaces of carriers place them in the dynamic pass box of the cooling zone and keep half an hour under the UV light.

Enter the sterility testing area through change rooms following the sterility testing area entry procedure as per SOP No.

After entering the sterility testing area, ensure that the air sampler is fully charged

Disinfect the outer surface of the SS carrier placed in the dynamic pass box and take it inside.

Take out the items from the SS bin and start the monitoring using the procedures mentioned below.

Settling Plate exposure (Passive air sampling):

Expose the agar medium plates at the locations according to the pre-defined locations and settle plate exposure schematic diagrams mentioned in the annexure.

Exposure method.

Bring each plate to the pre-defined locations.

Open the lid of the plate carefully.

Place the plate containing the medium at the location. Place the plate on the settle plate exposure stand if it is provided for that location.

Place the lid beside this plate’s internal side down.

Expose the plates for 4 hours.

After completion of exposure time, close the medium plate with the lid carefully.

Label each plate on the bottom side with the location code, date of exposure, media Lot No, and date of media preparation.

Place all the plates in SS carriers.

Perform the monitoring by settling plates daily once under dynamic conditions if the activity is there or once a week if there is no activity.

Volumetric Air Sampling (Active air sampling by sieve impaction method):

Perform the volumetric air sampling in the locations (1000 liters / Location) according to the pre-defined locations and volumetric air sampling schematic diagrams as per Annexure No.

Perform Air sampling with a sieve impaction Air Sampler, as per SOP NO.

Disinfect the sieve after sampling every location.

Perform the volumetric air sampling starting from high clean area location to low clean area location sequentially.

After completion of the test, label each plate on the bottom side with the location code, date of exposure, media Lot No, and date of media preparation.

Place all the plates in SS carriers.

Perform the monitoring by volumetric air sampling once a week.

Surface Monitoring by Swabs and 55 mm Surface contact (RODAC) plates:

Perform the surface monitoring at the locations according to the pre-defined locations and surface monitoring schematic diagrams mentioned in Annexure No.

Perform the surface monitoring by following two methods based on the location as per Annexure No.

Swab method:

Aseptically open the test tube containing the swab and take out the sterile swab partially, press the swab to the internal walls of the tube gently to remove excess saline and take it out completely.

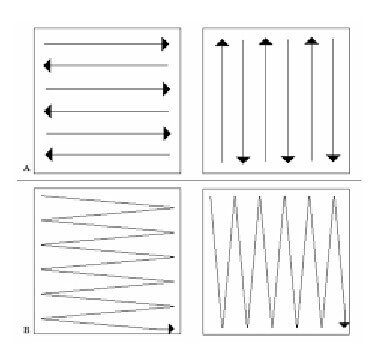

Swab about 25 cm2 (5 cm x 5cm) area in the direction specified in Figure: 1

Figure: 1

1) Horizontal Strokes

2) Vertical strokes by rotation of Swab 5 cm at 90o after horizontal strokes 5 cm.

Place the swab in the saline-containing tube and close it.

After completion of the test label each plate on the bottom side with the location code, date of sampling, media Lot No, and date of media preparation.

Perform the sampling in all the locations as per the sampling plan using the same procedure.

Place all the swab tubes and place the stands in SS carriers.

55 mm surface contact (RODAC) plates :

Perform the surface monitoring in flat surfaces as per annexure No. using 55 mm surface contact (RODAC) plates.

Carefully open the RODAC plate, invert, and touch gently with the convex surface of agar to the surface to be monitored. Press the plate firmly to expose the entire agar surface to the area to be sampled.

Slowly take back the plate and close the plate with the lid. Take care not to leave any traces of agar medium on the surface monitored.

Disinfect the sampled area and clean it with a sterile moping pad.

After completion of the test, label each plate on the bottom side with the location code, date of sampling, media Lot No, and date of media preparation.

Perform the sampling in all the locations as per the sampling plan using the same procedure.

Place all the plates in SS carriers.

Perform the monitoring daily once at the end of Sterility testing (before cleaning), or fortnightly if there is no activity.

Personnel Monitoring 55 mm Surface contact (RODAC) plates:

Perform the personnel monitoring for the personnel working in the sterility testing area using 55 mm Surface contact (RODAC) plates.

Perform the personnel monitoring for four locations and it should include both hands. Perform the sampling in any two other locations. Refer to the schematic diagram mentioned in Annexure No. for sampling locations.

Sampling:

Perform the personnel monitoring at the locations using 55 mm Surface contact (RODAC) plates as per Annexure No.

Carefully open the RODAC plate, invert, and contact the surface of agar to the surface to be monitored. Press the plate firmly to expose the whole surface of the agar to the sample surface.

Slowly take back the plate and close the plate with the lid. Take care not to leave any traces of agar medium on the surface monitored.

After completion of the test, label each plate on the bottom side with the location code, date of sampling, media Lot No, and date of media preparation.

After completing the sample collection, place all the plates in SS carriers.

Perform the monitoring daily at the end of the activity while coming out of the sterility area. (before leaving).

After environment and personnel monitoring are over, keep the SS carriers in the dynamic pass box and come out through the exit change rooms.

Bring all the swab tubes/plates/cassette carriers to the incubator room for incubation.

Perform the testing of swabs in the MLT testing room.

First, vortex the saline solution contained in each tube along with swab and filters through a sterile 0.45 µm membrane filter and rinse the membrane filter three times with 100 ml of 0.1% peptone water and place the membrane filter on a pre-incubated SCDA medium plate. Use a different filter holder for each swab.

Incubation:

Incubate all plates/cassettes of environmental monitoring and personnel monitoring tests at 20-25 0C for 72 hours and at 30-35 0C for a further 48 hours. Observe the plates/cassettes after 72 hours and after a further 48 hours and record the results in respective report formats as per the given annexures.

Documentation:

Record the test details of settling plate exposure for the Sterility testing area in the report given as per Annexure No.

Record the test details of Volumetric Air sampling for the Sterility testing area in the report given as per Annexure No.

Record the test details of Surface Monitoring by Swabs and 55 mm Surface contact (RODAC) plates in the Sterility testing area in the report given as per Annexure No.

Record the test details of Personnel Monitoring Surface contact (RODAC) plates in the Sterility testing area in the report given as per Annexure No.

Acceptable levels:

Verify that the monitoring results are within the acceptable levels mentioned in the particular annexure.

Forms and Records (Annexures)

Report of Viable Particles Monitoring by Settle Plate Method

Report of Viable Particles Monitoring by Volumetric Air Sampling

Report of Surface Monitoring for Viable Particles by Swabs and Surface Contact Plates

Report of Personnel Monitoring for Viable Particles by Surface Contact Plates