Temperature mapping protocol

A well-designed protocol will help ensure that the mapping study is correctly carried out. To cover the full range of temperature regimes, a standard protocol can be used to map any storage area in the facility

The mapping protocol should contain the following sections:

a. Approval page and change control history

b. Acronyms and glossary

c. Description and rationale

d. Scope

e. Objectives

f. Methodology

g. Mapping report template

h. Annexes as needed, including templates for the mapping report.

Approval page and change control history

If the protocol has been prepared by a qualified third party, it should be authorized by the responsible person within the commissioning organization.

Acronyms and glossary:

Define the acronyms and technical terms used in the protocol.

Description and rationale:

Describe the installation to be mapped and outline the reasons for carrying out the exercise.

Scope:

Clearly define the scope and purpose of the mapping study.

A temperature-mapping study may be carried out –

- In an empty storage area – for example during operational qualification of a new cold room or

- In a storage area where TTSPPs are already being kept – for example after alterations have been made to an existing cold room.

If storage areas are affected by seasonal temperature variations, at least two temperature-mapping studies may be needed in each area to observe the effect of seasonal variation.

- one should be carried out during the warmest season and

- Second during the coldest season.

the worst-case scenarios and will establish whether the mapped area is able to maintain stable temperatures throughout the year.

Two-season mapping is not necessary for cold rooms and freezer rooms.

Systematic issues related to the season can be identified. Seasonal effects need to be separated from any other site-specific issues arising at the times when the comparative studies are done.

Objectives

- Mapping of temperature variations within the selected storage areas. Typically these areas include freezer rooms, cold rooms, and warehouses. Packing areas, loading bays, and other areas in which temperature-sensitive products are stored, or are temporarily held when in transit may also be mapped and monitored, although temperatures in these areas are likely to fluctuate when doors are opened.

- Measuring temperature variations at each location within the chosen area, by day of the week and time of day.

- Documenting high and low-temperature fluctuations caused by the environmental control systems operating at the time of the study – for example, heating, cooling, and ventilation.

- Identifying potential airflow issues that may be the cause of temperature variations.

- Recommending where TTSPPs can safely be stored in the mapped area and where they must not be stored. These recommendations should take account of any temperature deviations identified during the study as well as the approved temperature range(s) for the products being stored in the area.

- Identifying the best places to locate temperature sensors for routine monitoring in circumstances in which a monitoring system is to be installed. If a monitoring system is already installed, identify the best places to relocate temperature sensors (if necessary).

- Making recommendations for any remedial actions needed to overcome the problems identified in the study

Methodology

The following activity must be completed before the mapping protocol can finally be approved.

Step 1 – select EDLMs:

Selection of EDLM for mapping-

The device has sufficient memory for the intended duration of the study and the selected recording interval.

All loggers must have a NIST-traceable 3-point calibration completed and valid (within the current year), and have an error of no more than ± 0.5 °C at each calibration point. Valid calibration certificates for each of the data loggers used in the study must be included in the mapping report.

Some EDLMs with built-in batteries and a limited life is not designed to be recalibrated; otherwise, calibration should be done annually.

Calibration temperature points used for the calibration of EDLMs should cover the required temperature range for each of the areas being studied.

Calibration temperature points should be

- one calibration point below the low end of the range,

- one calibration point in the middle of the range, and

- one calibration point above the high end of the range.

To ensure consistency, use only one type of device per mapping study.

Provide a link to the manufacturer’s user instructions so that those responsible for programming and reading the devices understand how to perform these actions correctly.

It may be appropriate to include an EDLM device that is able to monitor door openings programmed so that the readings on the temperature monitoring devices can be aligned with door opening times.

Step 2 – designate the mapping team:

- Identify and list the team members. Record their signatures and initials so that signed records can be traced back to the person who prepared the document.

- Ensure that all team members receive the training needed to perform their assigned tasks.

Step 3 – survey the site:

Conduct a site survey of the area(s) to be mapped. The following information is required for each thermally separate area being mapped:

- Length, width, and height.

- Drawing of each area, showing elements, such as shelving or pallet racking, that may have an effect on the even heating or cooling of the space and which may affect its temperature stability.

- The shelving or pallet racking will be used to place the EDLMs, so it is important to record these components accurately.

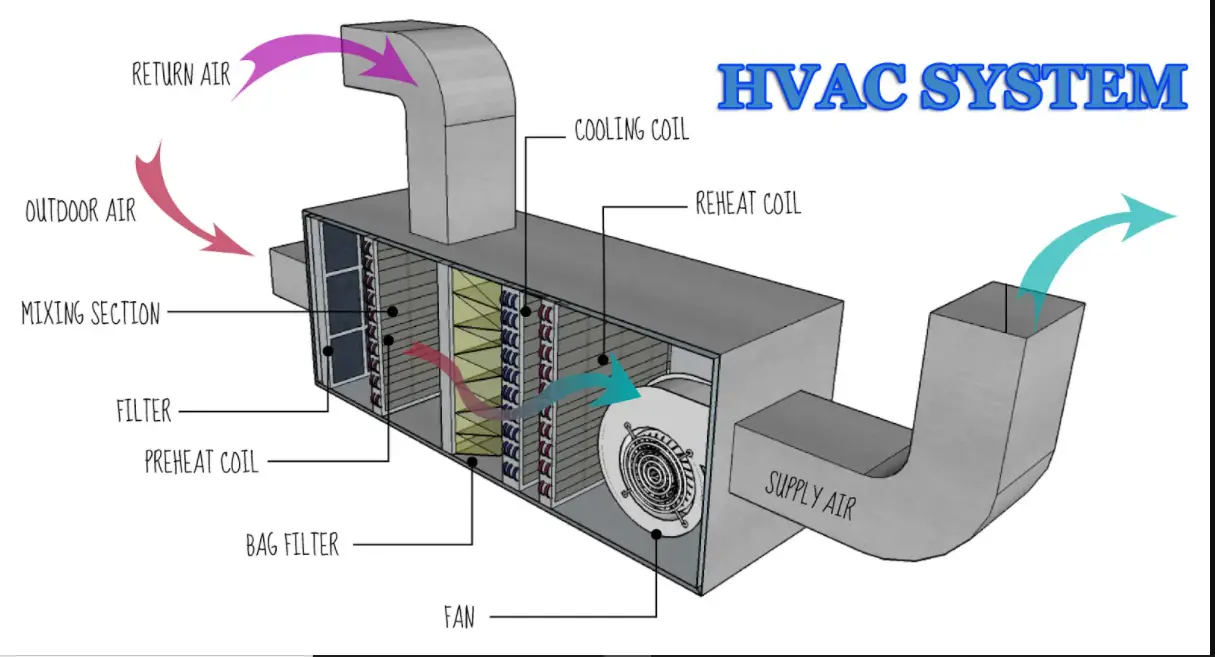

- The location of heating and cooling components, including air distribution outlets and/or ceiling fans.

- The location of existing temperature recording sensors and temperature control sensors.

Step 4 – establish acceptance criteria:

The protocol should define the required acceptance criteria, based on the type of TTSPPs being stored, clearly stating

the temperature limits that are allowable within the area to be mapped – for example +2.0 °C to +8.0 °C or +15.0 °C to +25.0 °C.

If the temperature-mapping study is designed to include door opening(s), the door opening parameters (frequency and duration) should be defined. The temperature should be maintained within the defined temperature limits except for a maximum of 30 minutes following the door opening.

Step 5 – determine EDLM locations:

A risk-based approach can be applied to define these locations.

Length and width:

EDLMs should be arranged in a grid fashion along the width and length of the area so that the area is reasonably covered, with EDLMs located every 5–10 meters. The chosen sensor grid should take into account of:

- The layout of the area (e.g. whether it is square or includes alcoves).

- The degree to which shelving and products may affect airflow. where products are placed.

- The positions of EDLMs should coincide with locations where TTSPPs are actually stored or planned to be

stored. - For example, it may be unnecessary to fit EDLMs in areas such as the upper part of high-loading bays.

Height: At each point on the grid, arrange EDLMs vertically as follows:

- If the ceiling height is 3.6 meters or less, position EDLMs directly above one another at high, medium, and low levels (e.g. one EDLM at floor level, one at 1.2 meters, and one EDLM at 3.0 meters.

- If the ceiling height is greater than 3.6 meters, EDLMs can be arranged in vertical arrays at the bottom, middle (multiple), and top of the space. For instance, for a storage area 6 meters in height, EDLMs can be positioned in each grid location at heights of 0.3 meters, 1.8 meters, 3.6 meters, and 5.4 meters.

Step 6 – record EDLM, monitoring sensors, and thermostat locations:

- Record the EDLM locations on a temperature data logger location table

- Record the location identification and set point for each thermostat in the storage area

Step 7 – label and program the EDLMs:

- Label each EDLM with a unique ID, taken from the temperature data logger location table.

- Enter the manufacturer’s serial number on the temperature data logger location table.

- Recording the serial number ensures that the device can be traced to its calibration certificate.

- Program each device, ensuring that the recording interval is the same – typically this should be set between 1 and 15 minutes. Set the same start time for all units.

- The readings downloaded from individual devices cannot be time-correlated. Make sure that the start time setting allows enough time for all the units to be fixed in position before recording begins.

Step 8 – fix EDLMs in position:

- Fix the EDLMs in position making sure that each one is placed exactly as shown on the temperature data logger location table and drawing.

- Position and fasten the devices so that they cannot be damaged or displaced during the course of routine store operations.

- Ensure that sufficient time is allowed for the EDLMs to be conditioned to the ambient temperature before the mapping exercise begins.

Step 9 – conduct the mapping exercise:

- There is no formal time limit for a mapping study. Typically, for warehouses and other ambient storage areas, it should be run for a minimum of seven consecutive days – including five working days and

two weekend days. - For temperature-controlled equipment which is not critically affected by diurnal or seasonal variations in ambient temperature (e.g. freezer rooms and cold rooms), the mapping study should be run for between 24 and 72 hours, or longer if justified.

- If the room is fitted with duplicate refrigeration units – with or without automatic changeover – it is essential to map temperatures over a period that includes the operation of both units running separately. preferably for a similar time period.

The temperature distribution in the room may vary depending on which system is running.

At the end of the study, collect the EDLMs and double-check their serial numbers and locations against the installation notes.

Step 10 – download and consolidate the data:

Download the EDLM readings and consolidate the data for analysis.

Reference: Temperature mapping of storage areas (WHO Technical Report Series, No. 961, 2011, Annex 9)