Emulsion & Role of Emulsifying Agents

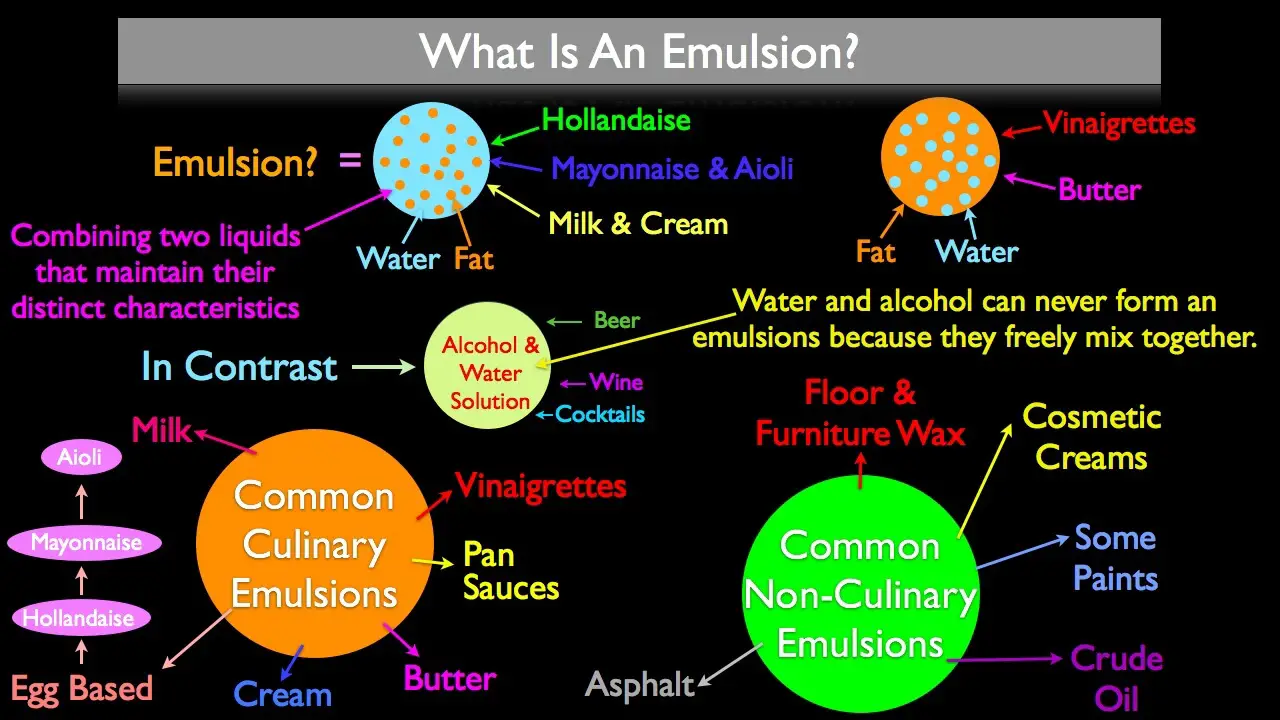

Emulsion refers to a colloidal dispersion where two liquids that do not mix are blended uniformly. It comprises small droplets of one liquid dispersed in another liquid. The stability of emulsions is of utmost importance in various industries such as food, pharmaceuticals, and cosmetics. Emulsifying agents are commonly employed to ensure stability. In this article, we will delve into emulsion and emphasize emulsifying agents’ role in their formation and stability.

Formation of Emulsion

Emulsions are created by reducing the interfacial tension between two liquids that do not mix, allowing them to mix at a molecular level. This process involves dispersing small droplets of one liquid within another. For instance, when oil and water are vigorously mixed, an oil-in-water (O/W) emulsion is formed, where oil droplets are dispersed in water. Conversely, if water is dispersed in oil, a water-in-oil (W/O) emulsion is produced.

Emulsifying Agents

Emulsifying agents, also known as surfactants or emulsifiers, play a vital role in the formation and stabilization of emulsions. They consist of both hydrophilic (water-loving) and lipophilic (oil-loving) components, enabling them to interact with both the dispersed and continuous phases of the emulsion. This interaction helps in reducing the interfacial tension and facilitating the formation of small, uniformly dispersed droplets.

There are several different types of emulsifying agents available, each with its own unique properties and applications. Some commonly used emulsifying agents include:

1. Natural Emulsifiers: These emulsifiers are derived from natural sources like lecithin, which can be found in egg yolks and soybeans, and acacia gum, a resinous secretion of the Acacia tree. Natural emulsifiers are often preferred in organic and natural products due to their biocompatibility.

2. Synthetic Emulsifiers: These emulsifiers are chemically synthesized compounds that possess emulsifying properties. Sodium lauryl sulfate is one example of a synthetic emulsifier commonly used in personal care products because of its excellent emulsification and foaming properties.

Surfactants, being the most prevalent emulsifying agents, possess a dual nature wherein one end is attracted to water while the other is attracted to oil. This unique attribute enables surfactants to create a steadfast layer around the dispersed oil droplets, effectively inhibiting their coalescence.

3. Polymeric Emulsifiers: These emulsifiers are long-chain polymers that create a protective layer around the dispersed droplets, preventing them from coalescing. Polyvinyl alcohol and cellulose derivatives are commonly used as polymeric emulsifiers.

4. Phospholipids: Phospholipids, such as phosphatidylcholine, are frequently used in pharmaceutical formulations. They exhibit excellent emulsifying properties and are compatible with biological systems.

By utilizing these different types of emulsifying agents, emulsion stability can be achieved.

The primary challenge in formulating emulsions lies in maintaining their stability over time. Emulsifying agents are of utmost importance in addressing this challenge. They create a protective film at the interface of the droplets, preventing them from merging and ensuring a consistent distribution. Moreover, emulsifying agents can also impact the viscosity, shelf life, and sensory properties of the emulsion.

Various factors can influence the stability of emulsions, such as temperature, pH, and the concentration of emulsifying agents. It is crucial to carefully select the appropriate emulsifying agent based on the emulsion’s specific application and desired properties.

Advantages of Emulsions:

Improved Stability:

One of the primary benefits of emulsions is their ability to enhance stability by creating a uniform mixture of two liquids that are normally unable to mix. Emulsifying agents form a protective barrier around dispersed droplets, preventing them from combining and separating.

Enhanced Bioavailability:

Emulsions play a crucial role in the pharmaceutical industry by significantly improving the bioavailability of certain drugs. The increased surface area of dispersed droplets allows for better absorption, resulting in more efficient drug delivery systems.

Versatility in Formulations:

Emulsions offer formulators a versatile platform for creating a wide range of products. Whether it’s food, cosmetics, pharmaceuticals, or agrochemicals, emulsions provide a means to incorporate both water-soluble and oil-soluble components into a single, stable formulation.

Texture and Sensory Appeal:

In the food and cosmetic industries, emulsions contribute to the desired texture and sensory properties of products. Whether it’s achieving a creamy texture in lotions or mayonnaise, emulsions are carefully manipulated to create the desired sensory experience.

Extended Shelf Life:

When properly stabilized, emulsions often have a longer shelf life compared to non-emulsified products. This increased stability can reduce the need for preservatives and contribute to the economic and environmental sustainability of products.

Disadvantages of Emulsions:

Sensitivity to Environmental Factors:

Emulsions can be influenced by various environmental factors, such as temperature and pH, which can lead to changes in their appearance, texture, and functionality. These external influences have the potential to cause emulsions to break down or become unstable.

Energy Intensive Production:

The production of emulsions, especially in high-shear processes, can be energy-intensive. To achieve and maintain a stable emulsion, significant mechanical energy is often required. This not only impacts the cost of manufacturing but also has implications for the environment.

Limited Compatibility of Ingredients:

It is important to note that not all ingredients are compatible with emulsion systems. Some substances can interfere with the stability of the emulsion or react with emulsifying agents, limiting the range of components that can be effectively incorporated.

Potential Allergies:

In cosmetic and personal care products, certain emulsifying agents may cause sensitivity or allergic reactions in some individuals. Manufacturers must carefully select emulsifiers to minimize the risk of adverse reactions in users.

Challenges in Large-Scale Production:

Scaling up the production of emulsified products can pose challenges. Maintaining the same level of stability and quality in large batches requires precise control of production conditions, which may not always be straightforward.

Applications of Emulsions:

Emulsions find wide applications in various industries, including the food industry, cosmetics and personal care, and pharmaceuticals. In the food industry, emulsions are crucial for creating sauces, dressings, and bakery items, as they ensure the desired texture and consistency of these products. Similarly, in cosmetics and personal care, emulsions are essential for formulating creams, lotions, and other products, as they contribute to stability and homogeneity, thereby enhancing their shelf life and usability. In the pharmaceutical industry, emulsions are utilized for drug delivery systems, where emulsifying agents play a vital role in improving the bioavailability and stability of certain medications.

In conclusion,

Emulsions and emulsifying agents find extensive use across different industries due to their ability to blend immiscible liquids and enhance product stability. Emulsifying agents play a critical role in the formation, stability, and sensory attributes of emulsions. By comprehending the principles behind emulsions and making informed choices regarding emulsifying agents, manufacturers can develop high-quality products with extended shelf lives and desirable characteristics.