Alcoa++ In a world where data plays a crucial role in decision-making and technological advancements shape various industries, the significance of data integrity cannot be emphasized enough. Alcoa, a company renowned for its commitment to excellence, extends the principles of Alcoa Plus Plus beyond aluminum production to prioritize data integrity …

Read More »Good Manufacturing Practices (GMPs)

Good Manufacturing Practices (GMPs) CGMPs provide systems that assure proper design, monitoring, and control of manufacturing processes and facilities. Good Manufacturing Practices (GMPs) are the basic manufacturing and environmental conditions required to produce pharmaceutical products. They ensure that ingredients, products, and packaging materials are handled safely and that pharmaceutical products …

Read More »Liquid pharmaceutical Preparations

Liquid pharmaceutical Preparations A solution is a homogenous one-phase system consisting of two or more components. →solvent + solute • The solvent is that phase in which the dispersion occurs and the solute is that component that is dispersed as small molecules or ions in the solvent. • Liquid preparations: …

Read More »PARENTERAL PREPARATIONS

PARENTERAL PREPARATIONS Parenteral preparations are sterile preparations intended for administration by injection, infusion, or implantation into the human or animal body. Parenteral preparations may require the use of excipients, for example, to make the preparation isotonic with respect to blood, to adjust the pH, to increase solubility, to prevent deterioration …

Read More »Most common types of pharmaceutical contamination

Most common types of pharmaceutical contamination Contamination can lead to objectionable results in the Pharma industry. It can conciliate the safety of patients, staff, and the environment – as well as affect the market. High standards of hygiene are important to maintain, only preventing the bio-burden levels by means of …

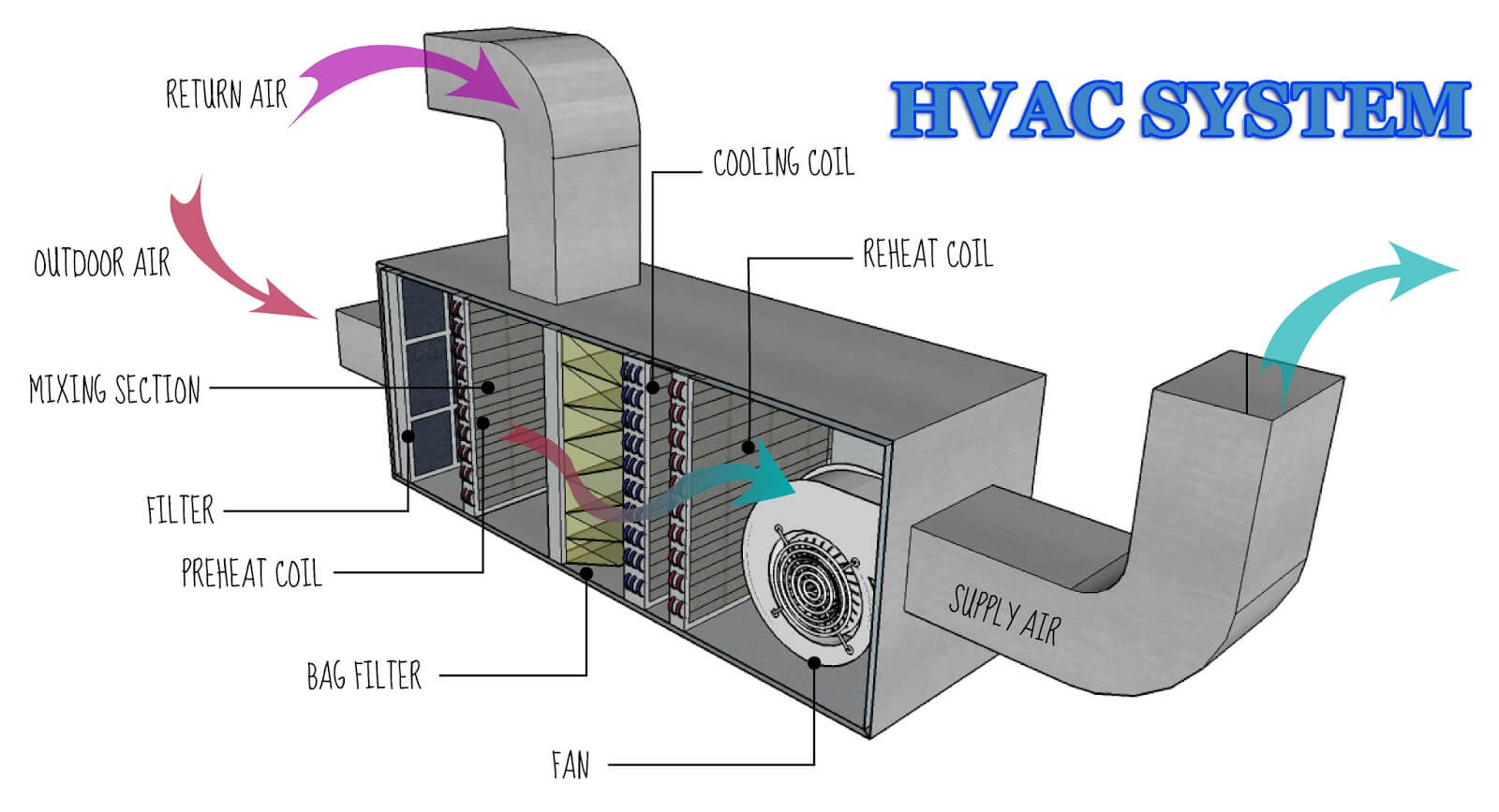

Read More »HVAC SYSTEM AND TEST FOR HVAC QUALIFICATION

HVAC SYSTEM AND TEST FOR HVAC QUALIFICATION What is HVAC? HVAC controls Temperature, Humidity, and Air quality inside a building. HVAC technology aims to provide thermal comfort and acceptable indoor air quality. HVAC system design is a sub-discipline of mechanical engineering, based on the principles of thermodynamics, fluid mechanics, and heat …

Read More »Change Management in Pharma

Change Management In Pharma Change Management in Pharma is a formal process for making planned and unplanned changes to the existing approved procedure and policy. The primary objective of Change Management in Pharma is to provide standardized methods and procedures to meet the change management requirements supporting operations. Change control …

Read More »Hold Time Study Protocol

Hold Time Study Protocol 1. Objective \ Scope 1.1. Hold time study data shall give the assurance of the maximum allowable hold times for bulk and in-process drug products. Generally, one lot can be used for validating hold times if any inconsistency results were observed then another two lots can …

Read More »CRITICAL AND MAJOR DEFICIENCIES

CRITICAL AND MAJOR DEFICIENCIES Compliance and enforcement measures are dependent upon a number of factors, including the significance of violations such as a “Critical” deficiency and a large number of “Major” deficiencies, the history of the site, potential risks to products, and assessment of the manufacturer’s proposed corrective actions. Where …

Read More »GMP Deficiencies in Pharmaceutical Industry “Critical and Major deficiencies”

GMP Deficiencies in Pharmaceutical Industry “Critical and Major deficiencies” The GMP Deficiencies findings of a Good Manufacturing Practice (GMP) inspection can have a substantial impact on both your organization and, subsequently, public health. If the GMP Deficiencies found are classified as significant, they may necessitate cessation of manufacturing activities and/or product withdrawal from the …

Read More »Air Handling Unit (AHU) and Working Principle

Air Handling Unit (AHU) and Working Principle An Air Handling Unit (AHU) is used to re-condition and circulate air as part of a heating, ventilating, and air-conditioning system. The basic function of the AHU is to take in outside air, re-condition it, and supply it as fresh air to a …

Read More »Isolators In Pharma Industry

Isolators In Pharma Industry Isolators are clean air devices providing complete separation between an aseptic process (hazardous/non-hazardous), the technical personnel, and the surrounding work environment. Isolators are generally used in applications requiring a high degree of protection from external elements or contaminants, and they can serve as alternatives to sophisticated …

Read More »Cleaning of Dispensing Area during Product Changeover

Cleaning of Dispensing Area during Product Changeover The area cleaning during Product Changeover: Start the cleaning operation of the ceiling and then to walls from top progressing to downwards. Clean the door and window glasses using a wet duster soaked with disinfectant solution. Clean the doors, door closure handles, and …

Read More »Dispatch of Finished Goods

Dispatch of Finished Goods Procedure Arrange the pallets in the warehouse in an orderly manner. Place the finished goods, product wise on the pallets in the Finished Goods store. Arrange one product on one pallet. Place the batch of the product wise. After QC and QA release of the batch …

Read More »Inspection, Sampling and Storage of Packing material

Inspection, Sampling, and Storage of Packing material Receipt and Inspection of Packing material Containers Upon receipt of packing material, the same shall be placed in the quarantine store attached to the Packing Material Store. In-charge of the Packing Material Store shall inform the QC Department for the inspection of containers …

Read More »Handling of Spillage of Materials

Handling of Spillage of Materials Procedure Spillage of any material shall be handled immediately when observed and effectively as per the procedure mentioned below : The personnel working in the concerned department shall immediately inform the Incharge of the concerned department about the spillage of material. The concerned department Incharge …

Read More »Entry & Exit procedure in warehouse area

Entry & Exit procedure in the warehouse area Push the door of the primary changing room and enter the room. Remove your street footwear and unwanted articles like wristwatches, ornaments, etc., and keep them in respective lockers. Sanitize your feet by using a soak system having disinfectant. Cross the cross-over …

Read More »Issuance of Packing Materials and transfer of Issued materials from Packing Material Store to Production

Issuance of Packing Materials and transfer of Issued materials from Packing Material Store to Production Procedure On the receipt of the requisition slip from the concerned production personnel for the manufacture of a product, the store In-charge shall ensure that the requisition slip bears the signatures of all the concerned …

Read More »Cleaning of Raw Material Store, Packing Material Store and Finished Goods Store

Cleaning of Raw Material Store, Packing Material Store and Finished Goods Store Procedure Collect all the waste material, dust settled over tables, floors, containers, furniture, fixtures & walls with the help of a vacuum cleaner. Clean the door, window glasses, door closures, handles, and all the hinges of the door …

Read More »Dispensing of raw materials and transfer of dispensed materials from RM store to Production

Dispensing of raw materials and transfer of dispensed materials from RM store to Production Pre-start-up activity for dispensing & Issuance of Raw material: On the receipt of the requisition slip from the production department for the manufacture of a product, the store personnel shall ensure that the requisition slip bears …

Read More »