1.Question: Definition of Good Manufacturing Practices (GMP) as per WHO ?

Answer:

WHO defines Good Manufacturing Practices (GMP) as “that part of quality assurance

which ensures that products are consistently produced and controlled to the quality

standards appropriate to their intended use and as required by the marketing authorization.”

GMP covers following Aspects

all aspects of the manufacturing process: defined manufacturing process.

validated critical manufacturing steps.

suitable premises, storage, transport.

qualified and trained production and quality control personnel.

adequate laboratory facilities.

approved written procedures and instructions.

records to show all steps of defined procedures have been taken.

full tractability of a product through batch records and distribution records.

and systems for recall and investigation of complaints.

2.Question: Definition of Validation as per WHO ?

Answer:

Validation is defined as the establishing of documented evidence which provides a high

degree of assurance that a planned process will consistently perform according to the

intended specified outcomes.

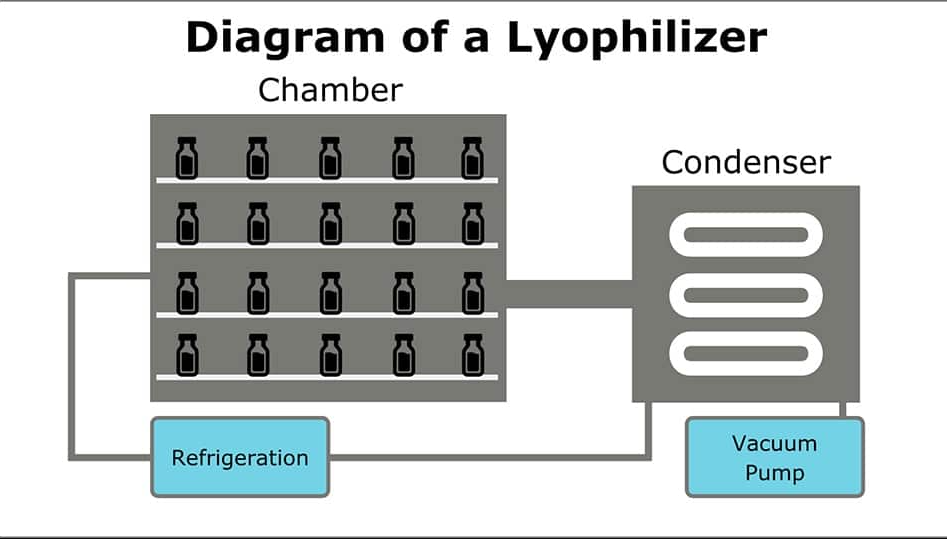

Validation studies are performed for analytical tests,equipment, facility systems (air, water, steam) and for processes such as the manufacturing processes, cleaning, sterilization, sterile filling, lyophilization,for the cleaning of glassware and the cleaning of the facility,for the sterilization process and for the sterility test etc.

3.Question: Types of Validation as per WHO ?

Answer:

Validation is Three type as per WHO that is

- Prospective Validation is data collected based on a pre-planned protocol

- Concurrent Validation is based on data collected during actual performance of a process already implemented in a manufacturing facility (validation data are collected during several runs of the on-going process and evaluated to determine if the process is valid).

- Retrospective Validation If a product has been in production for a long time, but has not been validated according to a prospective protocol and concurrent validation is not a realistic option in this situation we conduct retrospective validation. Retrospective analysis can only be made on a system, piece of equipment, or process which has not undergone any revision,repairs or modifications.

4.Question: What is the Validation Protocol as per WHO ?

Answer:

A documented plan, which is reviewed and approved prior to execution,for the test of a process, system, or piece of equipment. Upon completion,the protocol and results serve as the basis for the documentation that the process performs as intended.

5.Question: What is the Master Validation Plan as per WHO ?

Answer:

The Master Validation Plan is a document pertaining to the whole facility that describes

which equipment, systems, methods and processes will be validated and when

they will be validated.

VMP also provide the format required for each particular validation document (Installation Qualification, Operational Qualification and Performance Qualification for equipment and systems; Process Validation; Analytical Assay Validation), and indicate what information is to be contained within each document.

VMP Also indicate why and when re-validations will be performed, either after changes or relocation of equipment or systems; changes to processes or equipment used for processing; or for changes in assay methods or in equipment used in tests.

6.Question: What is the scope QI,OQ and PQ in Equipment and system qualification as per WHO ?

Answer:

The Qualification for equipment and systems are normally divided into three

segments: Installation Qualification, Operational Qualification and Performance Qualification,abbreviated as IQ, OQ, PQ.

For systems and equipment, Performance Qualification is often synonymous with Validation. Depending on the function and operation of some equipment, only IQ/OQ are required.

For equipment whose correct operation is a sufficient indicator of its function, and that are monitored and/or calibratedon a regular schedule (e.g. pH meter, incubator, centrifuge, freezer), the installation and operational qualifications are performed. Systems such as air, water, steam, and major equipment which perform critical support processes, such as sterilization (autoclave, oven), depyrogenation (oven or tunnel), or lyophilization, require installation,operational and performance qualifications.