DQ of CONTA BLENDER

TABLE OF CONTENT of DQ of CONTA BLENDER

- Objective

- Scope

- Responsibilities

- Machine description

- Operating control panel

- Main electric Panel

- Program of Bin Blender

- Program

- Data Program

- Spares

- Technical Specifications of Components & Sub-Components used/ bought outs

- Details of Utilities

- Identification of component for calibration

- Material of construction

- Enclosures

- Safety features and alarms

- FAT procedure

- Change control procedure

- Design qualification report

- List of Abbreviations

- OBJECTIVE

To design, engineer, and supply the Conta Blender 400/200/50 Ltrs (Model: BLD/NFLP/400-200-50) and to provide assurance that the machine is manufactured as per the URS and it complies with the Scope of Supply.

To prove that each operation proceeds as per the design qualification and the tolerances prescribed there in the document, are the same at utmost transparency.

- SCOPE

The scope of this qualification document is limited to the Design Qualification of Conta Blender 400/200/50Ltrs(Model: BLD/NFLP/400-200-50) . This qualification document is part of a validation activity for the Conta Blender 400/200/50Ltrs (Model: BLD/NFLP/400-200-50)

- RESPONSIBILITIES

- CLIENT

To check and approve the design qualification.

- MANUFACTURER

- To design, engineer and provide the complete technical details of the equipment pertaining to its design qualification viz.

- Machine overview

- General arrangement drawing,

- Equipment orientation with layout,

- Specifications of the sub-components/ bought out items, and their make, model & quantity, and backup records/ brochures,

- Details of Utilities,

- Identification of components for calibration

- Material of construction of all components

- Safety features and alarms

- To facilitate the client for the Factory acceptance test of the machine at their works/ site.

- To confirm the safe delivery of the equipment to the user site.

- To ensure that no un-authorized and or unrecorded design modifications shall take place. If at any point in time, any change is desired in the mutually agreed design, Change control procedure shall be followed and documented.

- To ensure the proper installation and commissioning of the equipment.

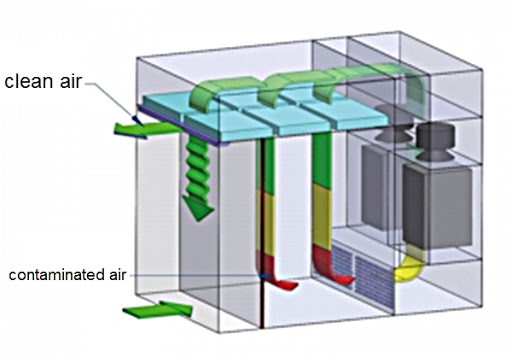

- MACHINE DESCRIPTION

The Blender is designed to mix/Blend different ingredients in dry Granules/power form in Blender Bin. Blender bin consisting of unmixed dry mass is clamped in bin holding arm .Bin holding arm is fixed on moving trolley. Trolley can be move up and down with the help of Hydraulic cylinder with chain and pulley arrangement. Hydraulic cylinders, Trolley, chain and pulley arrangement is housed inside the mast. Mast base is fixed on the floor and top is supported on the ceiling. Safety railing of SS304 with interlock is provided for safety of the operator. All the gaskets are of food grade silicone.

Product mass in the Bin can be rotated at preset RPM and preset time for the following:

- RPM setting

- Soft start

- Soft stop.

Complete equipment can be divided in the following sub sections:

- Mast consisting of Hydraulic cylinder, Guide Rollers and chain-pulley assembly.

- Bin Holding arm.

- Main panel consisting of Hydraulic power pack and hydraulic circuit, Electrical power panel, PLC (optional) and VFD.

- Operating panel consisting of push button, MMI (optional) and limit switch for safety railing.

- Bins (50/200/400 l) having butterfly valve at the discharge end, housed in SS 304 trolleys with PU caster wheel.

- Operating control panel

- The Non-flame proof and Flame proof control panels are made of SS304 sheet. It is located and mounted on the wall and on the safety railing pillar. Operating panel consist of

- MMI (E-300)

- Emergency switch

- Limit switch for safety railing interlock.

- The Non-flame proof and Flame proof control panels are made of SS304 sheet. It is located and mounted on the wall and on the safety railing pillar. Operating panel consist of

- Main Electric panel

The main Non-Flame proof Electrical power panel along with Hydraulic power pack is housed inside M S powder coated panel and is located in service/Technical area.

Main power panel consists of

- VFD & brake resister

- PLC

- Electrical power circuit

- Main ON/OFF switch.

- Programme of conta blender

PLC: Fx 1N 24 MR with extra module Fx 1N 1 DABD, Mitsubishi make (14 DI+10DO)

MMI: E-300 Mitsubishi make.

VFD: FRE E540 –(2.2) KW, 400V, Mitsubishi make.

- Program

- Blender is programmed for manual and auto mode. Lifting & lowering is manual, rotational RPM &timing is automatic.

- RPM of the Blender can be pre set and different RPM can be stored.

- Acceleration (Soft start) and Deceleration (Soft stop) time can be set per the requirement.

- Mixing /Rotation time can be pre set.

- Different products with different rotation time and RPM can be programmed.

- Inter locking is done for the rotation height/ position.

- Programming is done for the blender to stop at the right position i.e. vertical position, repeatedly after every mixing cycle.

- Display of actual RPM of the Bin on MMI with the help of Fx 1N 1 DABD analog output module.

- Data program

- Date

- Product name

- Batch no.

- Operator name.

- Batch size.

- Standard blending time.

- Print interval.

- Mixing, 3 level pass word

Print port is available for connecting to the printer.

Data can be stored in PC through software program like SCADA.

- Spares

- Hydraulic Flexible Hose Pipe – 3/8”BSP 2 Nos.

- Coil for 2-way solenoid valve, 24V DC 2 Nos.

- Hydraulic Cylinder Seal Kit 1 Set.

- Guide roller with 6205zz bearing 8 Nos

- TECHNICAL SPECIFICATIONS OF COMPONENTS & SUB –COMPONENTS USED / BOUGHT OUTS

| S.No. | DESCRIPTION | SPECIFICATIONS |

| 1. Equipment Description | ||

| a | Name | Conta Blender |

| b | Specification | Non Flame proof construction |

| c | Capacity | 400/200/50Ltrs (Bin Qty. = 3,3 and4 respec. ) |

| d | RPM | 5-16 |

| e | Model | BLD/NFLP/400-200-50 |

| f | Overall dimensions | 225x225x3080 (WxDxH) |

| g | Foundation Bolts (bottom) | Pin type Anchor Bolt (M12 x 6”) with SS 304 dome nut |

| h | Foundation Bolts (top) | Pin type Anchor Bolt (M12 x 4”) with

SS 304 dome nut |

| i | Mast center to Bin center | 1040mm |

| j | Minimum height of the bin holding arm from the ground | 500 mm |

| 2. Power Pack | ||

| a | Type | Hydraulic |

| b | Model | Solenoid operated, Single station, Double acting |

| c | Make | RP Make |

| 3. Power pack Motor | ||

| a | Type | TEFC, Non-Flame proof, Squirrel cage, three phase induction motor. |

| B | Model | Flange Mounted, |

| c | Capacity | 1.5HP x 1415 RPM |

| d | Make | Crompton Greaves |

| 4. Hydraulic Cylinder | ||

| Dimensions :- | ||

| a | Bore | 65 (dia)mm |

| b | Rod | 35(dia)mm |

| c | Stroke | 300mm |

| d | Stop Tube | 100 mm |

| 5. Worm Reduction Gear Box | ||

| a | Type | Worm Reduction Gear Box |

| b | Make | Bonfliglio |

| c | Reduction Ratio | 10:1 |

| d | Location | LHS / RHS |

| e | Qty | 02 nos. |

| 6. Drive Motors | ||

| a | Type | Non Flame Proof, 3 phase induction |

| b | Make | Bharat Bijlee |

| c | Model | Flange Mounted, |

| d | Capacity | 2HP |

| e | Location | LHS / RHS |

| f | Qty | 02 nos. |

| 7. Variable Frequency Drive | ||

| a | Type | E-Series, 400 V class AC drive |

| b | Model | FR-E 540-2.2 K |

| c | Capacity | 2.2 K |

| d | Make | Mitsubishi |

| 8. Pressure Gauge | ||

| a | Type | 2 ½” (dia) , Glycerin filled |

| b | Range | 0 – 280kg/cm2 |

| c | Mounting | Bottom mnt. , ¼”BSP |

| d | Make | Shreeji |

| 9. Programmable logical cont | ||

| a | Model No | Fx 1N 1DABD FX IN 24 MR |

| b | Make | Mitsubishi |

| 10. Man Machine Interface | ||

| a | Model No | E-300 |

| b | Make | Mitsubishi |

| 11. Limit Switch | ||

| a | CAT No. | NLL1 |

| b | Qty. | 02 Nos. |

| c | Make | Bhartia Cutler |

| d | Location | Upper / Lower |

| 12. Proximity Switch | ||

| a | Model | EGT18X80 AP 024 –2000L |

| b | Make | Tekknic Euchner |

| 13. Emergency Switch | ||

| a | Qty. | 01 No. |

| b | Location | Control Panel |

- DETAILS OF UTILITIES

| DESCRIPTION | SPECIFICATIONS |

| Electrical | |

| Phase | 3 Phase |

| Voltage | 415V |

| Frequency | 50 Hz |

- IDENTIFICATION OF COMPONENT FOR CALIBRATION

In the Conta Blender, following are the components, which needs calibration.

- Pressure Gauge (to measure Oil pressure of the power pack)

- MATERIAL OF CONSTRUCTION

| S. NO. | COMPONENT DESCRIPTION | MOC |

| 1 | Bin 400 Ltrs. (Qty. 3) | SS 316 |

| 2 | Bin 200 Ltrs. (Qty. 3) | SS 316 |

| 3 | Bin 50 Ltrs. (Qty. 4) | SS 316 |

| 4 | Control Panel | SS 304, |

| 5 | Mast Structure | MS, |

| 6 | Mast cladding | SS 304, |

| 7 | Container/Bin holding Arm | SS 316 L |

| 8 | Main Panel | MS, (Powder coated)

|

- ENCLOSURES

| S. No. | Description | Drawing No |

| 1 | General arrangement drawing of Conta blender | BLD-3402 |

- SAFETY FEATURES AND ALARMS

- MCB, Relay provided in the Main Panel

If power pack motor is overloaded to draw more current than the limit, the circuit will trip.

- Locking rod & bush arrangement is provided at the foot of the mast.

To prevent accidental mast swiveling while lifting & lowering the load.

- Pilot operated check valve (C I 10 S) on hydraulic cylinder

In case of hydraulic leakage during operation, check valve does not allow the load / Arm to come down.

- FAT PROCEDURE

Factory Acceptance Test Procedure shall be as follows:

After the completion of erection work of the machine, client shall be informed to perform the factory acceptance test (FAT).

Client shall perform the FAT at the manufacturer site and record all the data in the prescribed FAT document as per the details given below:

- Test criteria

- Design Verification Check list

- Deficiency & Corrective Action report

- Pre-installation requirements

- Final report

- CHANGE CONTROL PROCEDURE

Change in the agreed design shall be addressed through the well-defined Change control procedure.

- DESIGN QUALIFICATION REPORT

18.0 LIST OF ABBREVIATIONS

| cGMP | current Good Manufacturing Practices |

| GEP | Good Engineering practices |

| MS | Mild steel |

| NFLP | Non Flame Proof |

| SS | Stainless Steel |

| KW | Kilo Watt |

| DQ | Design Qualification |

| FAT | Factory acceptance test |

| LFT | Lift |

| VFD | Variable frequency drive |

| RPM | Revolution per minute |

| MMI | Man machine interface |

| SCADA | Supervisory control & data acquisition |

| MCB | Miniature circuit breaker |