Factory Acceptance Test of Automatic Capsule Filling Machine

Table of Contents

- System Information

- Protocol Details

- Protocol Approval from Customer

- The objective of this protocol

- Scope of this Protocol

- Definition of FAT and SAT

- Acceptance Criteria

- Responsibility

- Customer Requirements

- Performance Check Points & Testing

- Machine Sr. number details AF T Lab

- Factory Acceptance Report Approval

- Final Report

System Information

Supplier: Pam Pharmaceutical & Allied Machinery Co. Pvt. Ltd.

The objective of this Protocol

To test the equipment before dispatch as per URS / Customer’s requirements.

Scope of this Protocol

Functional Tests with placebo & or actual material.

Safety Functions verification

Reporting of results and deviations

Equipment inspection & acceptance by the customer

Definition of FAT and SAT

Factory Acceptance Tests (FAT)

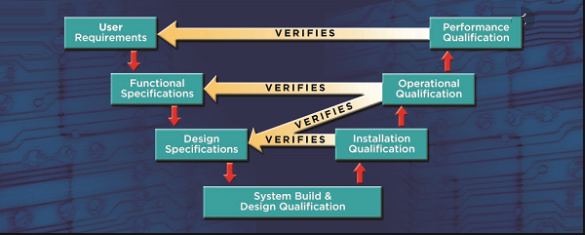

The FAT protocol is an inspection that includes both static and dynamic exhaustive testing of systems or major system components to support the qualification of equipment or a system. The tests must verify that all functionality detailed in the User Requirements Specification (URS) is embodied and performs as specified. It is written by the manufacturers and executed by the client or client representative.

Site Acceptance Tests (SAT)

The SAT is related to the FAT and also entails the inspection and dynamic testing of systems or major system components to support the qualification of equipment. This is written by the client and verifies that the installed functionality of the equipment meets or exceeds the operational requirements as specified in the equipment URS. The SAT is executed on completion of all commissioning tasks; but before the start of Installation Qualification execution.

Acceptance Criteria

FAT Protocol shall be referred for final Inspection of the equipment.

The Inspection Team shall note down their findings in the protocol after discussion with the vendor as per the details given in this protocol.

The inspection team may suggest the implementation of minor points at the vendor’s site.

On completion of FAT, the inspection team/vendor gives technical clearance of the equipment/system.

Responsibilities

Inspection

The customer is responsible for visiting the vendor’s site and completing the inspection based on this FAT Protocol.

Customer Requirements

Automatic Capsule filling Machine Model AF- T Lab

Change parts for powder Size # 4

Change parts for powder Size # 5

Change parts for powder Size # 0 (AF 25T)

Change parts for powder Size # 1 (AF 25T)

Change parts for pellet Size # 00 (AF 25T)

Vacuum Pump

Air displacement Unit Model ADU-100

Compact Air Displacement unit, Model CADU-100

Sorter Elevator Model SE-100

Interchangeable section for size 00

Interchangeable section for size 0

Interchangeable section for size-1

Interchangeable section for size-4

Interchangeable section for size-5

Automatic De-dusting and polishing machine Model DP-100

Empty capsule sorter Model ECS-100

Mini capsules sorter, Model MCS-100

Interchangeable section for size 00

Interchangeable section for size 0

Interchangeable section for size-1

Interchangeable section for size-4

Interchangeable section for size-5

Metal Detector, Model MD- 2000

Checkweigher, Model CW- 10

Product Conveying System, PCS 200

Performance check Points & Testing

Automatic Capsule Filling Machine Model: AF- T Lab

Machine specification & details

Voltage – Three phase 415 v 50 Hz

Single phase 220 v 50 Hz

Machine dimension

Output

Powder filling: 6000 capsules / hr. (AF T lab)

Powder filling: 25000 capsules / hr. (AF25T)

Pellet filling: 23,000 capsules / hr. (AF25T)

MMI –

Door – Acrylic

Machine mount –

Performance of the machine

Loading station

Check all the capsules get loaded in the bushes.

Separation of Cap / Body

Check cap/body gets separated after loading

Powder filling

Check that the slug is delivered into the body of the capsule without cutting.

Unopen ejection

Check all non-separated capsules get collected on an unopen collection box

Closing of filled capsule

Check all the capsules are closed and the lock length of the capsule is within +/- 0.2 mm of

# 00 – 23.5 mm, # 0 – 21.8 mm

# 1 – 19.5 mm , # 4 -14.5 mm

# 5 – 11.0 mm.

Ejection of capsules

Check all the filled are ejected without getting damaged

Total no. of capsules filled –Capsule size/Colour/No. of capsule filled

Filled capsule check – Denting/Telescoping/Unlocked/Folded

% Weight variation –Name of Powder / Pellet: Weight variation (Individual) 50 capsules, Weight variation (Group of 10 capsules)

Bush cleaning

Check for proper airflow from bush cleaning pins

Check for proper suction from bush-cleaning housing

The function of line machines

Sorter Elevator ( SE 100 )

No abnormal noise was observed.

Check that the sorter elevator sorts diametrically defective capsules & elevates empty capsules in the Automatic capsule-filling machine hopper

Check the function of the upper & lower-level sensor

Finish & aesthetics of the machine after final cleaning

Air Displacement Units (ADU 100)

No abnormal noise.

Check the direction of rotation of ADU & check for suction

Finish & aesthetics after final cleaning.

Compact Air Displacement Units ( CADU 100 )

No abnormal noise.

Check the direction of rotation of ADU & check for suction

Finish & aesthetics after final cleaning.

Dedusting & polishing (DP 100)

No abnormal noise.

Proper De dusting & polishing of the filled capsules

Finish & aesthetics after final cleaning.

Metal Detector ( MD 2000 )

Detection of Ferrous & Non-Ferrrous filled capsules.

Sorting of Ferrous & Non-Ferrous capsules in a separate box.

Checkweigher (CW 10 )

Sampling – Stroke base / Time base/manual.

Weight of capsule at intervals & alarms.

Weight variation report.

Empty Capsule Sorter ( ECS 100 )

No abnormal noise.

Check sorting of empty capsules from filled capsules.

Finish & aesthetics after final cleaning.

Mini Capsule Sorter (MCS 100)

- Check the proper assembly of change parts for the correct size of capsules.

- No abnormal noise.

- Function of the vibrator controller.

- Complete inspection of functional aspects (with filled capsules) & adjustment of critical settings.

- Check for the following diametrical defective 1) telescopic & heavy notches and 2) Loose capsules.

- Finish & aesthetics after final cleaning.

Product Conveying System (PCS 200)

Check, when the vacuum is on – proper suction of powder & intake gate is closed.

Check, when the vacuum is off – open the hopper gate & drop the powder.

Check, when PMM is on – Cycle stops.

Finish & aesthetics after final cleaning.

Alarms/interlocks verification

- Door open

- Air pressure low

- Line machines not working

- Overload of the main motor

- Metal detected in capsule

- Hand wheel “IN”

- Powder level low

- Pellet level low

- Capsule level low

- Individual Weight out of limit

- Average weight out of limit

- Over speed of the main motor.

Machine serial number details

Machine Details

Automatic Capsule Filling Machine Model: AF T Lab.

Vacuum pump

Air Displacement Unit, ADU 100

Compact Air displacement unit, CADU 100

De-dusting & polishing machine, DP 100

Empty Capsule Sorter, ECS 100

Mini Capsule Sorter, MCS 100

Sorter Elevator Unit, SE 100

Metal Detector, MD 2000

Check weigher, CW 10

Product Conveying System, PCS 200

Factory Acceptance Report

Final Report