Particle Size Determination Methods:

1. Sieving

2. Microscopy

3. Sedimentation rate method

4. Light energy diffraction

5. Laser holography

6. Cascade impaction

1. Sieving method:

• Range: 50 – 150 μm

• Simple, inexpensive

• If powder is not dry, the apertures get clogged.

2. Microscopy:

• Range: 0.2 – 100 μm

• Particle size can be determined by the use of calibrated grid background.

• Most direct method.

• Slow and tedious method.

3. Sedimentation method:

• Range: 1 – 200 μm

• Andreasen pipette is used.

4. Cascade impaction:

• The principle that a particle driven by an airstream will hit a surface in its path, provided that its inertia is sufficient to overcome the drug force that tends to keep in it in airstream.

5. Light energy diffraction:

• Range: 0.5 – 500 μm

• Particle size is determined by the reduction in light reaching the sensor as the particle, dispersed in a liquid or gas, passes through the sensing zone.

• Quick and fast.

6. Laser holography:

• Range: 1.4 – 100 μm

• A pulsed laser is fired through an aerosolized particle spray & photographed in three dimensional with holographic camera, allowing the particles to be individually imaged & sized.

• Particle size is characterized using these terms:

− Very coarse (#8)

− Coarse (#20)

− Moderately coarse (#40)

− Fine (#60)

− Very fine (#80)

Powder Flow Properties:

Flowability of powder and chemical stability depends on the habit and internal structure of a drug.

Habit is the description of the outer appearance of a crystal. A single internal-structure for a compound can have several different habits, depending on the environment for growing crystals. Different habits of crystals are given below.

• Powder flow properties can be affected by change in particle size, shape and density.

• The flow properties depend upon following-

(i) Force of friction.

(ii) Cohesion between one particle to another.

• Fine particle possesses poor flow by filling void spaces between larger particles causing packing & densification of particles.

• By using glidant we can alter the flow properties.

• e.g. Starch, Talc.

Determination of Powder Flow Properties:

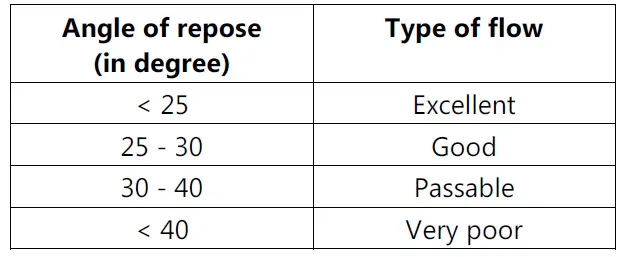

• By determining Angle of Repose.

• A greater angle of repose indicates poor flow.

• It should be less than 30° and can be determined by following equation:

tan θ = h / r

where, θ = angle of repose.

h = height of pile.

r = radius.

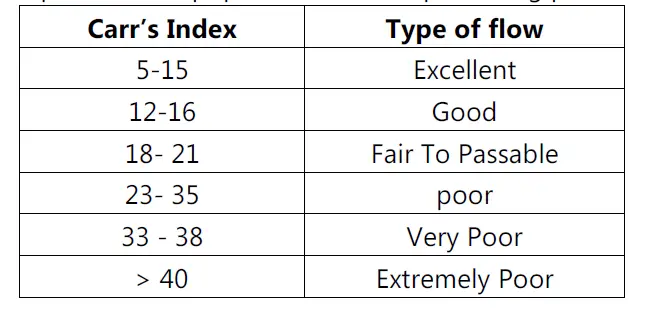

Measurement of free-flowing powder by compressibility:

• Also known as Carr’s index.

Car’s index (%) = (Tapped density − Poured density) / Tapped density × 100

Tapped Density:

• It is simple, fast and popular method of predicting powder flow characteristics.

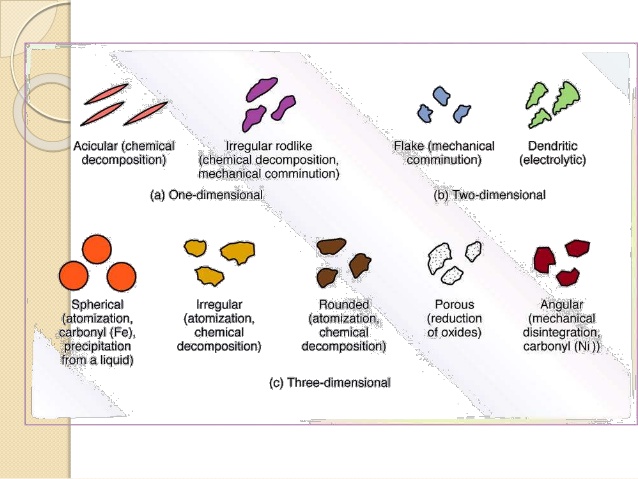

Particle Shape:

• Particle shape will influence the surface area, flow of particles, packing & compaction properties of the particles.

• A sphere has minimum surface area per unit volume.

• Therefore, these properties can be compared for spheres & asymmetric particles, in order to decide the shape.

Surface Area:

• Particle size and surface area are inversely related to each other.

• Smaller the drug particle, greater the surface area.

• Specific surface is defined as the surface area per unit weight (Sw) or unit volume (Sv) of the material.

• However size reduction is not required in following cases when drug is unstable.

• Degrade in solution form.

• Produce undesirable effects.

• When sustained effect is desired.

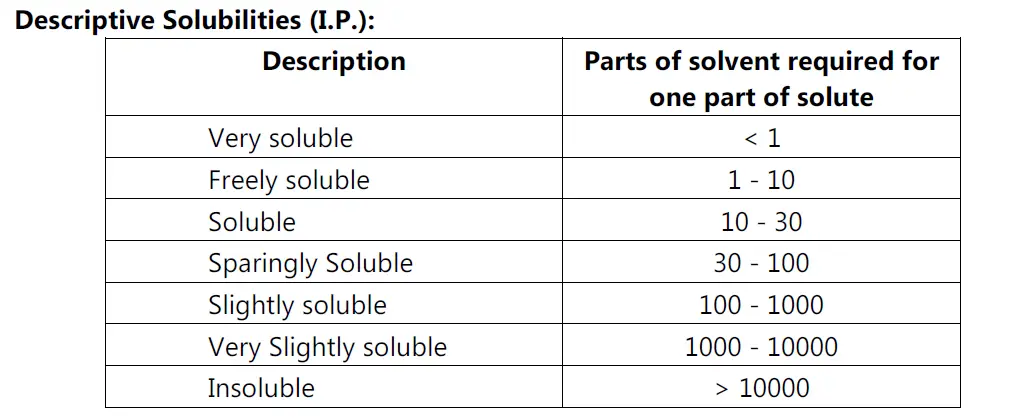

Solubility Analysis:

• Preformulation solubility studies focus on drug solvent system that could occur during the delivery of drug candidate.

• e.g. A drug for oral administration should be examined for solubility in media having isotonic chloride ion concentration and acidic pH.

• Analytic methods that are particularly useful for solubility measurement include HPLC, UV spectroscopy, Fluorescence spectroscopy and Gas chromatography.

• Reverse phase HPLC offer accurate and efficient means of collecting solubility data of drug.

For determination of solubility the following points should be considered:

• The solvent & solute must be pure.

• A saturated solution must be obtained before any solution is removed for analysis.

• The method of separating a sample of saturated solution from undissolved solute must be satisfactory.

• The method of analyzing solution must be reliable

• Temperature must be adequately controlled.

• General Method of Increasing

• the Solubility

• Addition of co-solvent

• pH change method

• Reduction of particle size

• Temperature change method

• Addition of Surfactant

• Complexation

• Applications of solubilization

• Drugs with limited aqueous solubility can be solubilized. These include oil-soluble vitamins, steroid hormones and antimicrobial agents etc.

• Both oil-soluble and water-soluble compounds can be combined in a single phase system as in case of multivitamin preparations.

• Solubilization may lead to enhanced absorption and increased biological activity.

• Drug absorption from ointment bases and suppositories also increased.

• Aqueous concentrates of volatile oils can be prepared by solubilization.

• Example: soaps used for solubilising phenolic compounds for use as disinfectants-Lysol, Roxenol etc.

• Barbiturates, anticoagulant, alkloidal drugs are dissolved with polysorbate by solubilization.

Formulation Challenges with Poorly Soluble Compounds:

• Poor dissolution rate

• Low and variable bioavailability

• More potential for food effect

• Inability to deliver high doses for toxicity studies

• Difficulty in developing parenteral formulations Stability:

• Stability is the extent to which a product retains (throughout its period of storage and use, i.e., its shelf life) the same properties that it possessed at the time of its manufacture.

• One of the principles of dosage form design is to ensure that the chemical integrity of drug substances is maintained during the usable life of the product.

• Three types of stability concern the pharmacists:

(i) Chemical: Each active ingredient retains its chemical integrity within the specified limits.

(ii) Physical: The original physical properties (including appearance, taste, color and odor) are retained.

(iii) Biological: Sterility is retained (No microbial growth).