PROCEDURE FOR CLEANING, OPERATION AND CALIBRATION OF MICROMETER SCREW GAUGE

To lay down a procedure for Operation and calibration of micrometer screw.

This procedure is applicable for Operation and calibration of micrometer screw.

MICROMETER SCREW GAUGE : A Micrometer is a measuring device used for taking the exact measurement of an object. It is also known as micrometer screw gauge.

The Micrometer Screw Gauge:

The micrometer screw gauge consists of a U-shaped frame that securely holds the instrument’s spindle and anvil. The frame is designed to rotate around a threaded screw, which is commonly referred to as the spindle. This spindle is spun using a thimble. On the other hand, the anvil serves as the flat measuring surface that comes into contact with the target object. By rotating the thimble, the spindle and anvil can be brought closer together to firmly clamp the object.

The fundamental concept behind the micrometer screw gauge lies in the principle of screw mechanics. As the spindle is turned, it travels along the screw threads and gradually approaches the anvil. This movement allows the spindle and anvil to come together and securely clamp the object being measured. To indicate the measurement, the thimble is equipped with a pointer or scale that responds to the motion of the spindle. This precise dial accurately displays the reading obtained from the micrometer screw gauge.

The micrometer screw gauge is composed of several components:

1. A U-shaped measuring framework made of steel, which has a precision range of approximately 25-50 mm.

2. A spindle made of hardened steel, featuring a screw thread. The pitch of the screw is 0.5 mm, and it has been meticulously machined to ensure utmost accuracy.

3. The object being measured is positioned on a flat surface called an anvil, which is also made of hardened steel.

4. The thimble, affixed to the tip of the spindle, serves as a unit of measurement and is calibrated in micrometers.

To properly interpret the reading on a micrometer screw gauge:

To ensure a secure grip on the instrument by placing your thumb and three fingers inside the U-shaped frame.

Rotate the thimble in an anticlockwise direction to open the jaws and insert the object to be measured between the spindle and anvil.

Once the object is in place, rotate the thimble in a clockwise direction to clamp it securely between the spindle and anvil.

To determine the measurement, align the horizontal line on the thimble with the horizontal line on the barrel.

The measurement can be read from both the main scale and the thimble scale, which are both marked in millimeters (micrometers).

The additional measurement is indicated in micrometers on the thimble scale.

By adding the readings from the main scale and the thimble scale, you can obtain the final measurement in millimeters or micrometers.

RESPONSIBILITY

QA Department Person:

To used instrument as per defined procedure

PROCEDURE

SAFETY/PRECAUTION/EHS

Before use ensure that instrument is calibrated.

Cleaning Procedure

Clean the Micrometer screw before & after each use.

Clean the Micrometer screw with the help of dry, clean, lint free cloth.

Operating Procedure

Diagram of an External Micrometer

Keep the micrometer in stable room temperature before starting the measuring process. Check Zero error before measurement & adjust if necessary.

Hold the micrometer from its heat isolation plate.

Rotate the ratchet anticlockwise allowing sufficient space between the anvil and the spindle to accommodate the object to be measured.

Place the object to be measured between the anvil and the spindle.

Spin the ratchet clockwise until the spindle just meets the object.

Keep spinning the ratchet gently until 3 clicks are heard.

Check that both the anvil and the spindle are touching the object evenly.

Set the lock nut while the micrometer is still on the object.

Remove the object from the micrometer.

Read off the value from the Sleeve scale to obtain reading to the nearest half millimeter.

Read off the value from the thimble scale that is parallel with the reference line of the Sleeve scale.

Add both below values obtained from Without Vernier scale and With Vernier scale to obtain the total measurement reading.

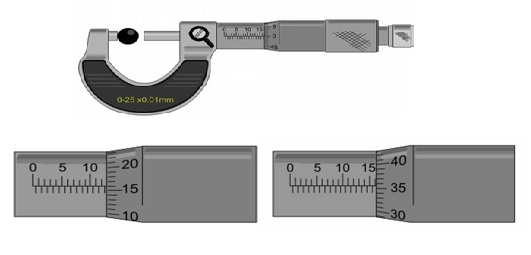

Micrometer reading example:

Without Vernier scale

EXAMPLE 1

Sleeve scale reads= 12.50mm

Thimble scale reads= 0.16mm

Total Measurement = 12.66mm

EXAMPLE 2

Sleeve scale reads = 16.00mm

Thimble scale reads = 0.35mm

Total Measurement = 16.35mm

With Vernier scale

Sleeve scale reads = 6.00mm

Thimble scale reads = 0.21mm

Vernier scale reads = .003mm

Total Measurement = 6.213mm

Reset the lock nut to the unlock position.

Turn the ratchet clockwise to slightly close the micrometer prior to its storage.

Calibration Frequency

Calibration shall be performed by outside agency.

Calibration Frequency: Yearly (± 30 Days)

Maintenance

Inspect the micrometer for any signs of damage, such as indications that it might have been dropped.

Check that both spindle and anvil tips are flat, free from scratches, dents and chipped edges.

Move the thimble through its entire range (i.e. 25 mm) to check that it moves smoothly.

Perform the zero point alignment test (see 6.3.5).

To clean the tips of the anvil and the spindle:

Rub off any visible dirt, dust and grit with a lint free cloth.

Close the micrometer all the way with a piece of paper clamped in between.

Pull the paper out whilst rubbing the tips of the spindle and the anvil clean.

Precautions

The micrometer is a highly heat sensitive instrument and should be stored at room temperature.

Hold the micrometer from its heat isolation plate whilst handling to prevent heat transfer from hand of user to the micrometer.

The object to be measured should also be kept at room temperature since this may also affect the reading.

Do not over tighten the micrometer as this can lead to deformation of both the anvil and spindle and the object being measured.

Store the micrometer in its appropriate storage compartment to prevent any wearing of the anvil and/or spindle.

Store the micrometer with the anvil and spindle not in contact with each other so that any temperature fluctuations will not stress the instrument.

Measure the desired object a number times to ensure that the reading obtained is accurate.

Do not operate abruptly, drop or strike the micrometer.

Also Read – QUALIFICATION OF CONTRACT TESTING LABORATORY