Load Pattern & Justification for Steam Sterilizer

APPROVAL SIGNATURES

The signing of this approval page of the load pattern indicates agreement with the qualification approach described in the PQ protocol. If any modification in the load pattern becomes necessary, a revision through change control shall be prepared, checked, and approved. Wherever applicable revalidation of the modified load pattern shall be carried out.

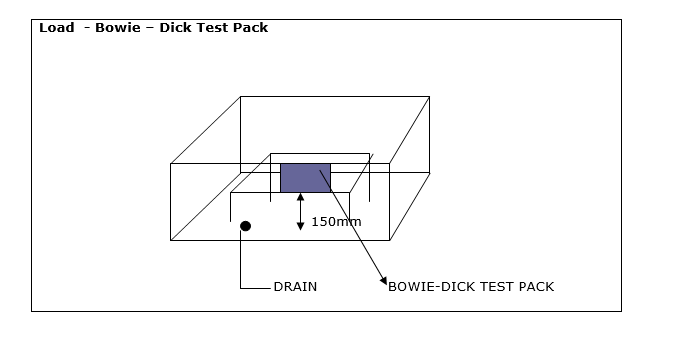

Location of the Bowie – Dick Test Pack

Schematic representation of the bowie-dick test pack placement in the sterilizer chamber

In Built Temperature Sensor Placement In The Chamber And Justification For The Selection Of Location

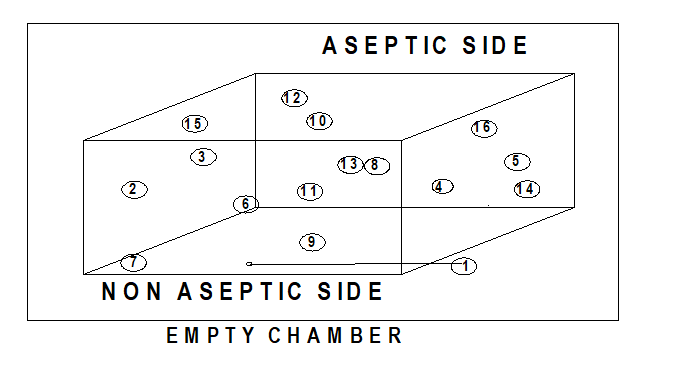

Temperature Sensor Placement In The Empty Chamber And Justification For The Selection Of Location

Schematic representation of temperature sensor placement in the empty chamber

Justification for the selection of locations for the temperature sensor placement in the empty chamber

| Sensor No. | Location In The Chamber | Justification For Location Selection |

| 1 | In the active Chamber Drain (Near RTD -01) | This is the location for the reference measurement point of the sterilizer, which controls the sterilization cycle. Hence important to compare the achieved temperature distribution results (strip chart/printout of sterilizer) with the results from the data logger. |

| 2 | Near RTD -02 | As these are temperature-recording probes at different points. It is necessary to verify/compare the temperature distribution obtained with a strip chart/printout from the sterilizer |

| 3 | Near RTD – 03 | |

| 4 | Near RTD – 04 | |

| 5 | Near RTD – 05 | |

| 6 | Non-sterile door middle |

Any conduction of heat through the door may cause a temperature drop at that particular point. |

| 7 | Non-sterile door left corner bottom | |

| 8 | Non-sterile door right corner top | |

| 9 | Chamber middle bottom | To know the temperature distribution in these regions |

| 10 | Chamber middle top | |

| 11 | Chamber middle | |

| 12 | Sterile door left corner top |

Any conduction of heat through the door may cause a temperature drop at that particular point. |

| 13 | Sterile door middle | |

| 14 | Sterile door right corner bottom | |

| 15 | Steam on let left side | To verify the probability of excess temperature near the steam inlet. |

| 16 | Steam in let the right side |

(NOTE: The temperature sensors shall be placed in the pre-determined locations with predetermined sensor numbers corresponding to the data logger channels).

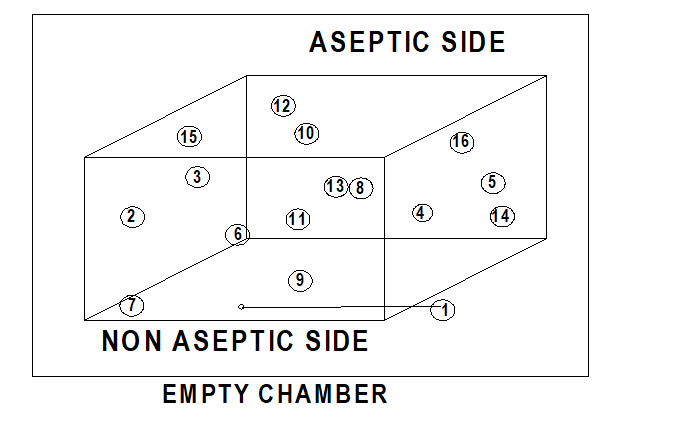

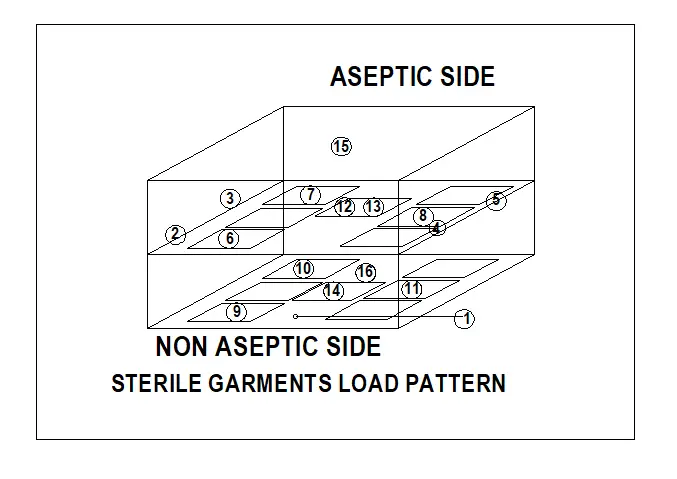

Temperature Sensor Placement And Justification For Location Selection (Garment Load Maximum)

Schematic representation of temperature sensor placement in the garment load

Justification for the selection of locations for the temperature sensor placement in the garment load

| Load Details | |

| 12 pairs of aseptic area gowning | Each one number of trunk, pair of booties, and headgear in one cloth bag. Four such bags are placed side by side as one layer in the trolley and three such layers are loaded amounting to 12 pairs. |

| One number of glove packs | Each contains 12 pairs of powder-free latex gloves. |

| 12 numbers of lint-free mopping dusters | Wrapped using parchment paper and arranged side by side |

| Sensor No. | Location In The Chamber | Justification For Location Selection |

| 1 | In the active Chamber Drain | This is the location for the reference measurement point of the sterilizer, which controls the sterilization cycle. Hence important to compare the achieved temperature distribution results (strip chart/printout of sterilizer) with the results from the data logger. |

| 2 | Near RTD -02 | As these are temperature-recording probes at different points. It is necessary to verify/compare the temperature distribution obtained with a strip chart / printout from the sterilizer |

| 3 | Near RTD – 03 | |

| 4 | Near RTD – 04 | |

| 5 | Near RTD – 05 | |

| 6 | Inside garments pack -01 | To verify the temperature penetration in the innermost portion of these packs. |

| 7 | Inside garments pack -03 | |

| 8 | Inside garments pack -05 | |

| 9 | Inside garments pack -07 | |

| 10 | Inside garments pack -09 | |

| 11 | Inside garments pack -11 | |

| 12 | Inside mopping dusters pack top | |

| 13 | Inside mopping dusters pack bottom | |

| 14 | Inside the glove pack | |

| 15 | Chamber middle top | To verify the temperature distribution above the packs in the bottom rack. |

| 16 | Chamber middle bottom |

(NOTE: The temperature sensors shall be placed in the pre-determined locations with predetermined sensor numbers corresponding to the data logger channels).

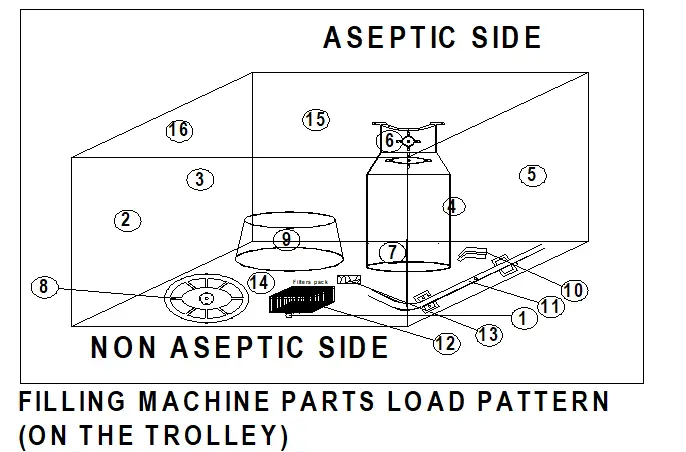

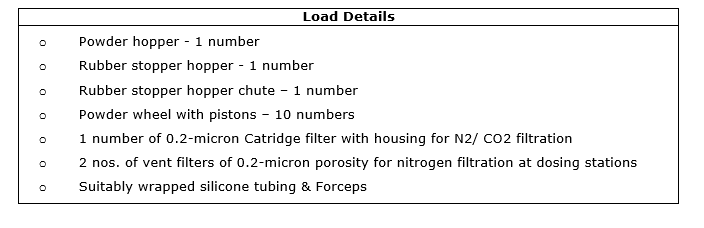

Temperature Sensor Placement In The Machine Parts Load

Schematic representation of temperature sensor placement in the filling machine parts load

Justification for the selection of locations for the temperature sensor placement in the filling machine parts load

| Sensor No. | Location In The Chamber | Justification For Location Selection |

| 1 | In the active Chamber Drain | This is the location for the reference measurement point of the sterilizer, which controls the sterilization cycle. Hence important to compare the achieved temperature distribution results (strip chart/printout of sterilizer) with the results from the data logger. |

| 2 | Near RTD -02 | As these are temperature-recording probes at different points. It is necessary to verify/compare the temperature distribution obtained with a strip chart / printout from the sterilizer |

| 3 | Near RTD – 03 | |

| 4 | Near RTD – 04 | |

| 5 | Near RTD – 05 | |

| 6 | Powder hopper top | To verify the temperature penetration in the innermost portion of these parts. |

| 7 | Powder hopper bottom | |

| 8 | Index wheel port | |

| 9 | Rubber stoppers hopper | |

| 10 | Dust collector set | |

| 11 | Rubber stoppers chute | |

| 12 | Sterilizing grade filter and tubing pack | |

| 13 | Accessories (forceps etc) | |

| 14 | Chamber middle bottom | To verify the temperature distribution at these points during the sterilization cycle. |

| 15 | Chamber middle top | |

| 16 | Near steam inlet |

(NOTE: The temperature sensors shall be placed in the pre-determined locations with predetermined sensor numbers corresponding to the data logger channels).

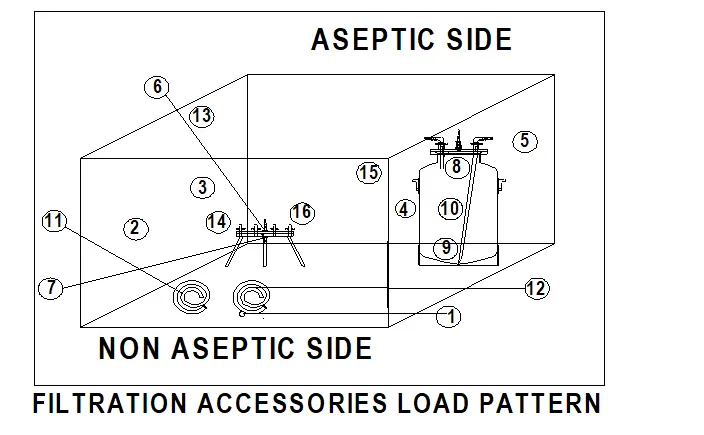

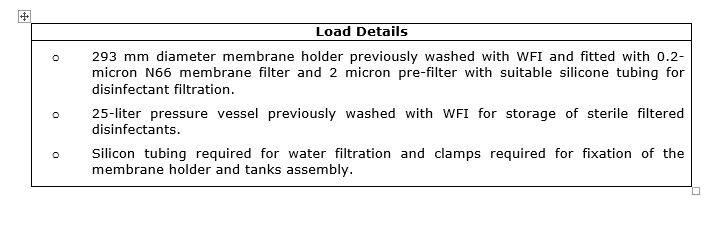

Temperature Sensor Placement In The Filtration Accessories Load

Schematic representation of temperature sensor placement in the filtration accessories

Justification for the selection of locations for the temperature sensor placement in the filtration accessories load

| Sensor No. | Location In The Chamber | Justification For Location Selection |

| 1 | In the active Chamber Drain | This is the location for the reference measurement point of the sterilizer, which controls the sterilization cycle. Hence important to compare the achieved temperature distribution results (strip chart/printout of sterilizer) with the results from the data logger. |

| 2 | Near RTD -02 | As these are temperature-recording probes at different points. It is necessary to verify/compare the temperature distribution obtained with a strip chart/printout from the sterilizer |

| 3 | Near RTD – 03 | |

| 4 | Near RTD – 04 | |

| 5 | Near RTD – 05 | |

| 6 | The membrane holder inside the top | To verify the temperature penetration in the innermost portions of the loaded items. |

| 7 | The membrane holder inside the bottom | |

| 8 | Pressure Vessel inside top | |

| 9 | Pressure Vessel inside bottom | |

| 10 | Pressure Vessel inside the middle | |

| 11 | Inside Silicon tubing | |

| 12 | Inside Silicon tubing pack | |

| 13 | Near steam inlet | To verify the temperature distribution at these points during the sterilization cycle. |

| 14 | Near the non-sterile door middle | |

| 15 | Near the sterile door middle | |

| 16 | Chamber middle |

(NOTE: The temperature sensors shall be placed in the pre-determined locations with predetermined sensor numbers corresponding to the data logger channels).

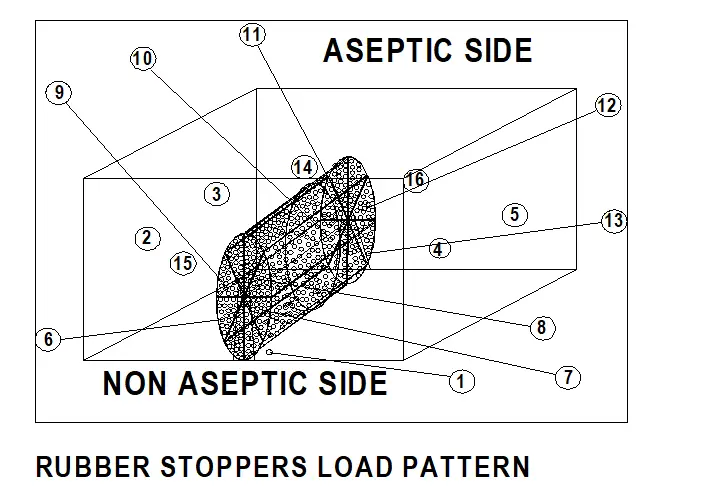

Temperature sensor placement in the rubber stoppers load

Schematic representation of temperature sensor placement in the rubber stopper load

Justification for the selection of locations for the temperature sensor placement in the rubber stopper load

| Sensor No. | Location In The Chamber | Justification For Location Selection |

| 1 | In the active Chamber Drain | This is the location for the reference measurement point of the sterilizer, which controls the sterilization cycle. Hence important to compare the achieved temperature distribution results (strip chart/printout of sterilizer) with the results from the data logger. |

| 2 | Near RTD -02 | As these are temperature-recording probes at different points. It is necessary to verify/compare the temperature distribution obtained with a strip chart / printout from the sterilizer |

| 3 | Near RTD – 03 | |

| 4 | Near RTD – 04 | |

| 5 | Near RTD – 05 | |

| 6 | Cassette 01 with stoppers | To verify the temperature penetration in the innermost portions of the loaded items. |

| 7 | Cassette 02 with stoppers | |

| 8 | Cassette 03 with stoppers | |

| 9 | Cassette 04 with stoppers | |

| 10 | Cassette 05 with stoppers | |

| 11 | Cassette 06 with stoppers | |

| 12 | Cassette 07 with stoppers | |

| 13 | Cassette 08 with stoppers | |

| 14 | Chamber middle top | To verify the temperature distribution at these points during the sterilization cycle. |

| 15 | Near the non-sterile door middle | |

| 16 | Near the sterile door middle |

(NOTE: The temperature sensors shall be placed in the pre-determined locations with predetermined sensor numbers corresponding to the data logger channels).

NOTE: It is not possible to insert the temperature sensors in the Rotating carriage of the bung processor during Sterilization and drying as the carriage rotates during the sterilization and drying process. Hence the basket drive of the equipment has been intentionally stopped and the sensors are introduced into the static carriage during this heat penetration study. This simulates the worst case study of stationary load for sterilization and drying.

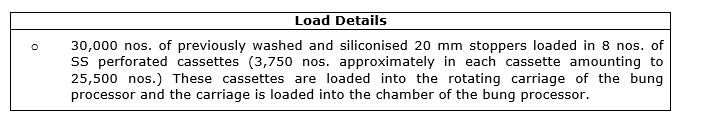

Temperature Sensor Placement In The Rubber Stoppers Holding Canisters

Schematic representation of temperature sensor placement in the rubber stopper holding canister load

Justification for the selection of locations for the temperature sensor placement in the rubber stopper holding canister load

| Sensor No. | Location In The Chamber | Justification For Location Selection |

| 1 | In the active Chamber Drain | This is the location for the reference measurement point of the sterilizer, which controls the sterilization cycle. Hence important to compare the achieved temperature distribution results (strip chart/printout of sterilizer) with the results from the data logger. |

| 2 | Near RTD -02 | As these are temperature-recording probes at different points. It is necessary to verify/compare the temperature distribution obtained with a strip chart/printout from the sterilizer |

| 3 | Near RTD – 03 | |

| 4 | Near RTD – 04 | |

| 5 | Near RTD – 05 | |

| 6 | Inside canister -01 | To verify the temperature penetration in the innermost portions of the loaded items. |

| 7 | Inside canister -02 | |

| 8 | Inside canister-03 | |

| 9 | Inside canister -04 | |

| 10 | Inside canister -05 | |

| 11 | Inside canister -06 | |

| 12 | Inside canister -07 | |

| 13 | Inside canister -08 | |

| 14 | Near the non-sterile door middle | To verify the temperature distribution at these points during the sterilization cycle. |

| 15 | Near steam inlet | |

| 16 | Chamber middle |

(NOTE: The temperature sensors shall be placed in the pre-determined locations with predetermined sensor numbers corresponding to the data logger channels).

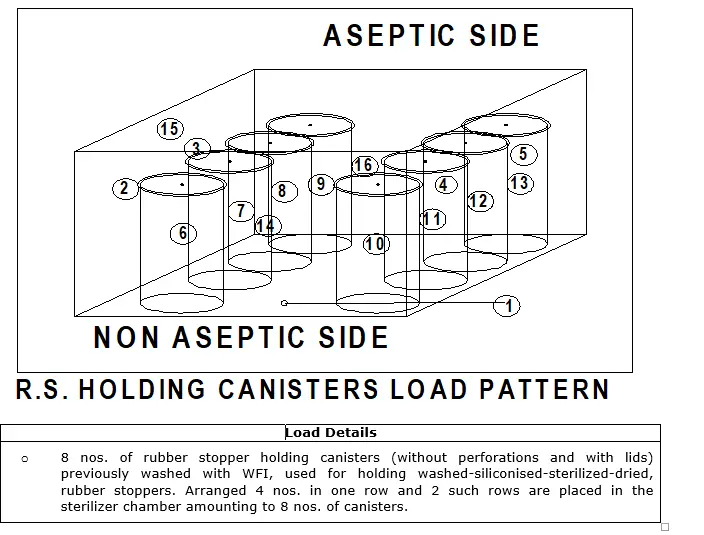

Temperature sensor placement in the media vessels with WFI

Schematic representation of temperature sensor placement in the media vessels (with WFI) load

Justification for the selection of locations for the temperature sensor placement in the media vessels (with WFI) load

| Sensor No. | Location In The Chamber | Justification For Location Selection |

| 1 | In the active Chamber Drain | This is the location for the reference measurement point of the sterilizer, which controls the sterilization cycle. Hence important to compare the achieved temperature distribution results (strip chart/printout of sterilizer) with the results from the data logger. |

| 2 | Near RTD -02 | As these are temperature-recording probes at different points. It is necessary to verify/compare the temperature distribution obtained with a strip chart / printout from the sterilizer |

| 3 | Near RTD – 03 | |

| 4 | Near RTD – 04 | |

| 5 | Near RTD – 05 | |

| 6 | Inside vessel –1 (top) | To verify the temperature penetration in the innermost portions of the loaded items. |

| 7 | Inside vessel – 1 (bottom) | |

| 8 | Inside vessel –2 (top) | |

| 9 | Inside vessel – 2 (bottom) | |

| 10 | Inside vessel –3 (top) | |

| 11 | Inside vessel – 3 (bottom) | |

| 12 | Inside vessel –4 (top) | |

| 13 | Inside vessel – 4 (bottom) | |

| 14 | Near the non-sterile door middle | To verify the temperature distribution at these points during the sterilization cycle. |

| 15 | Near steam inlet | |

| 16 | Chamber middle |

(NOTE: The temperature sensors shall be placed in the pre-determined locations with predetermined sensor numbers corresponding to the data logger channels).