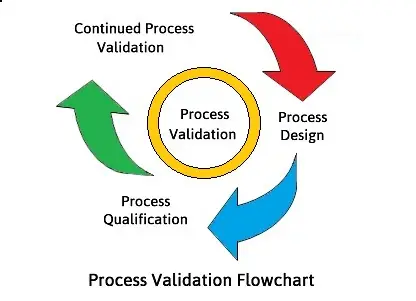

Process validation (Continuous process verification) for finished products

Process validation can be defined as documented evidence that the process, operated within established parameters can perform effectively and reproducibly to produce a medicinal product meeting its predetermined specifications and quality attributes (ICH Q7).

Continuous process verification has been introduced to cover an alternative approach to process validation based on a continuous monitoring of manufacturing performance and also based on the knowledge from product and process development studies and/or previous manufacturing experience.

Process validation incorporates a lifecycle approach linking product and process development, validation of the commercial manufacturing process, and maintenance of the process in a state of control during routine commercial production.

This document is intended to provide guidance on the process validation information and data to be provided in regulatory submissions for the finished dosage forms of chemical medicinal products for human and veterinary use. The general principles also apply to active substances. However, information on validation of non-sterile active substances is not required in the dossier.

A medicinal product is developed by a traditional approach or an enhanced approach, the manufacturing process should be validated before the product is placed on the market. In exceptional circumstances, concurrent validation may be accepted.

Process validation should confirm that the control strategy is adequate to the process design and the quality of the product.

The validation should cover all manufactured strengths and all manufacturing sites used for the production of the marketed product.

A bracketing approach may be acceptable for different strengths, batch sizes, and pack sizes. However, validation must cover all proposed sites.

Process validation data should be generated for all products to demonstrate the adequacy of the manufacturing process at each site of manufacture.

The possibility to implement continuous process verification if an enhanced approach to development has been performed or where a substantial amount of product and process knowledge and understanding has been gained through historical data and manufacturing experience.

A combination of traditional process validation and continuous process verification may be employed. The in-line, on-line, or at-line monitoring that is often utilized for continuous process verification, provides substantially more

information and knowledge about the process and might facilitate process improvements.

Traditional process validation

Traditional process validation is normally performed when the pharmaceutical development and/or process development is concluded, after scale-up to production scale and prior to marketing of the finished product.

As part of the process validation lifecycle, some process validation studies may be conducted on pilot scale batches if the process has not yet been scaled up to the production scale. It should be noted that pilot batch size should correspond to at least 10% of the production scale batch (i.e. such that the multiplication factor for the scale-up does not exceed 10).

For solid oral dosage forms, batch size should generally be 10% of the maximum production scale or 100,000 units whichever is the greater. Where the intended batch size is less than 100,000 units, the predictive value of the pilot batches may be limited and a justified approach should be followed.

For other dosage forms, the pilot batch size should be justified taking into account risk to the patient of failure of the dosage form.

The process validation scheme to be followed should be included in the dossier. The process validation scheme should include a description of the manufacturing process, the tests to be performed and acceptance criteria, a description of the additional controls in place and the data to be collected.

In certain cases, however, it is considered necessary to provide production scale validation data in the marketing authorization dossier at the time of regulatory submission, for example, when the product is a biological/biotech product or where the applicant is proposing a non-standard method of manufacture

In these cases, data should be provided in the dossier on a number of consecutive batches at the production scale prior to approval.

The number of batches should be based on the variability of the process, the complexity of the process/product, process knowledge gained during development, supportive data at commercial scale during technology transfer, and the overall experience of the manufacturer. Data on a minimum of 3 production scale batches should be submitted unless otherwise justified.

Data on 1 or 2 production scale batches may suffice where these are supported by pilot-scale batches and a justification as highlighted above.

Continuous process verification

Continuous process verification is an alternative approach to traditional process validation in which manufacturing process performance is continuously monitored and evaluated (ICH Q8).

It is a science and risk-based real-time approach to verify and demonstrate that a process that operates within the predefined specified parameters consistently produces material that meets all its critical quality attributes (CQAs) and control strategy requirements.

In order to enable continuous process verification, companies should perform, as relevant, extensive in-line, on-line, or at-line controls and monitor process performance and product quality on each batch.

Relevant data on quality attributes of incoming materials or components, in-process material, and finished products should be collected. This should include the verification of attributes, parameters and endpoints, and assessment

of CQA and critical process parameter (CPP) trends.

Process analytical technology (PAT) applications such as NIR spectroscopy with or without feedback loop (e.g. endpoint determination of blend homogeneity, determination of granules surface area, determination of content uniformity with large sample size) and Multivariate Statistical Process Control (MSPC) can be viewed as enablers for continuous process verification.

Scope and extent of continuous process verification will be influenced by a number of factors including:

- prior development and manufacturing knowledge from similar products and/or processes.

- The extent of process understanding gained from development studies and commercial manufacturing experience.

- The complexity of the product and/or manufacturing process.

- The level of process automation and analytical technologies used.

- For legacy products, with reference to the product lifecycle, process robustness, and manufacturing history since the point of commercialization as appropriate.

A description of the continuous process verification strategy including the process parameters and material attributes that will be monitored, as well as the analytical methods that will be employed and Actual data generated during continuous process verification at production scale should be available at the site for inspection.

The stage at which the process is considered to be under control and the validation exercise completed prior to the release of the product to the market, and the basis on which that decision will be made and should include a justification for the number of batches to be used based on the complexity and expected variability of the process and existing manufacturing experience of the manufacturing site.

Continuous process verification would be considered the most appropriate method for validating continuous processes.

Continuous process verification can be introduced at any time in the lifecycle of the product. It can be used for

- The initial commercial production,

- To re-validate commercialized products as part of process changes or

- To support continual improvement.

Hybrid approach

It may be necessary to use either the traditional process validation or the continuous process verification approach for different steps within the manufacturing process.

It should be clear in the dossier which approach to validation has been taken for which steps in the manufacturing process.

The validation requirements in terms of batch size and number of batches would depend on the extent to

which continuous process verification has been used.

For non-standard processes, if continuous process verification does not address the critical unit operation(s) should be applied unless otherwise justified.

Design space verification

A design space will normally be developed at laboratory or pilot scale. During scale-up, the commercial process is generally conducted and validated in a specific area of the design space, defined as the target interval or Normal Operating Range (NOR).

During the product lifecycle, moving from one area to another within the design space (i.e. change in the NOR) may represent higher or unknown risks not previously identified during the initial establishment of the design space.

Design space verification -To verify that all product quality attributes are still being met in the new area of operation within the design space.

If the parameters investigated during the development of the design space have not been shown to be scale-independent and the process has been validated using traditional process validation, design space verification would be required and a verification protocol should be provided in the dossier.

If continuous process verification has been utilized, this may contribute towards ensuring the validity of the design space throughout the product lifecycle. A design space verification strategy should be included as part of the continuous process verification strategy.

Depending on the change and the extent of movement within the design space (i.e. distance from validated target/NOR or new area of design space with higher or unknown risk) protocols for verification may include controls of quality attributes (QA’s) and process parameters (PP’s) not included in the routine control system (e.g. monitoring or testing of QA’s and PP’s that are expected to be scale dependant and when applicable, equipment dependant).

It is not necessary to verify entire areas of the Design Space or the edge of failure. In principle, more than one area of the design space should be verified but a stepwise approach taking into consideration the need to adjust the NOR within the approved design space during the product lifecycle is acceptable.

Scale-up

In order to avoid the repetition of lengthy and costly tests, it is necessary to gather information during properly designed development and process optimization studies, when scaling up from laboratory through pilot to production scale.

Such information provides the basis for justification that scale-up can be achieved without a consequent loss in quality.

Where ranges of batch sizes are proposed, it should be justified that variations in batch size would not adversely alter the CQAs of the finished product.

It is envisaged that those parameters listed in the process validation scheme will need to be re-validated once further scale-up is proposed post-authorization unless the process has been proven to be scale independent or continuous process verification is employed.

Post-approval change control

Clearly defined procedures are needed to control changes proposed in production processes. Such procedures should

control planned changes, ensure that sufficient supporting data are generated to demonstrate that the revised process will result in a product of the desired quality, consistent with the approved control strategy, and ensure that all aspects are thoroughly documented and approved including whether regulatory approval is needed by way of variation.

Standard vs. non-standard methods of manufacture

Only relevant for processes that have been validated using traditional process validation. It is not relevant for those processes where continuous process verification is employed. Full production-scale data should be provided in

the dossier for non-standard products or processes which were validated using traditional process validation.

It is possible for the applicant to justify that the production process can be considered standard for a particular manufacturer/site taking into account the risk to the patient of failure of the product or process.

Such justifications are assessed on a case by case basis, but the information provided by the applicant (for each manufacturing site) should include:

- Experience with the same or essentially similar product or process (number of products authorized

/ marketed in the EU/EEA and number of batches (including information on the scale) manufactured). - TThe names/ marketing authorization numbers in the relevant EU/EEA member state should be

provided. - Amount of knowledge gained during the development of the product (number and scale of batches

manufactured at each manufacturing site involved). - History of GMP compliance of manufacturing sites for that type of process

- The applicant should clearly state whether they consider the manufacturing process to be standard or nonstandard and the justification for their decision for new marketing authorization applications.

Reference: Guideline on process validation for finished products – information and data to be provided in regulatory

submissions