SOP ON MICROBIOLOGIST QUALIFICATION IN MICROBIOLOGY LAB

PURPOSE: To provide a procedure for Best Microbiological Lab Practices in Microbiology Lab in Microbiology Lab.

SCOPE: This procedure is applicable for Microbiologist Qualification in the microbiology Lab.

ATTACHMENTS :

Microbiologist Qualification Report

Microbiologist Qualification Inward

RESPONSIBILITY:

Quality control Department Laboratory Attendant person (Microbiology Lab)/ Designee: To follow this procedure during Microbiologist Qualification in the Microbiology Lab.

Head-QC /Designee: To ensure the activity as per SOP & implementation of SOP.

Head-QA/Designee: To ensure the implementation & compliance of the defined system.

Plant Head: To ensure the implementation of the defined system.

PROCEDURE:

SAFETY/PRECAUTION/EHS

Entry into the Microbiology section should be restricted & only authorized personnel shall allow minimizing the microbial load.

Every person who is performing the microbiological analysis should be qualified before performing the analysis

Entry & Exit procedures should be followed.

All the doors of the respective areas of the laboratory should be kept in closed condition & Approved SOP shall be followed for the handling of micro equipment.

All aseptic testing should be done under Grade A & during aseptic work, hthe and should be sanitized by filtered 70% IPA.

Procedure

Each and every person who are performing the microbiological analysis should be qualified before performing the analysis for the following microbiological tests

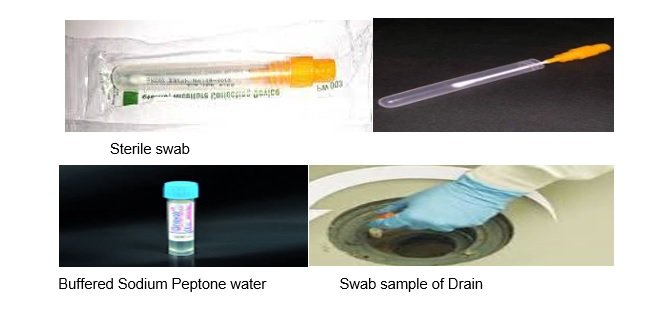

- Microbial Limit Test (MLT) of product

- Microbiological analysis of water

- Sterility Test

- Bacterial Endotoxin Test (BET)

Before starting the qualification study, the person for whom the qualification is being done should be gone through the employee training program as per the respective SOPs.

The person being qualified for microbiological analysis should know the microbiological techniques and best microbiological lab practices before starting the qualification activity.

For each microbiological analysis test, a separate General Test Procedure (GTP) is available, which shall be provided to the analyst and clearly instructed to follow the same procedure as mentioned in GTP.

A request for the sample (which was previously complied with and released) shall be sent to the QA department after getting approval from the QA head to issue the required quantity of sample from the retained/control samples.

Each sample shall be coded with unique coding as ABYYMQNNN (Original detail of sample like Product Name, Batch No. etc. shall not be disclosed to the analyst). AB is denoted as company code, YY denotes the year, MQ is denoted as Microbiologist Qualification and NNN is denoted as serial number & enter.

For water sample, freshly sampled water shall be provided to the analyst in sterilized sampling bottles. For MLT, sterility and BET, sample in its original primary packing/container shall be provided to analyst with ensuring proper intactness and closure of primary pack.

For water sample, analyst need to perform the analysis as per current version GTP. For finished sample (used for MLT, sterility and BET) maximum period of 10 days is allowed from the date of sampling.

Microbiologist Qualification shall involve determining competency on following:

- Understanding of the GTPs of the test and analysis performed by the analyst.

- Knowledge about the instruments used by the analyst and ability to use them according to SOP and GTPs for performing the analysis.

- Evaluation of the analytical results and reporting.

Each analyst shall be qualified immediately after joining and thereafter once in a period of two years. The frequency of revalidation can be based if change the job profile of the analyst (i.e. change the field of analysis)

All qualitative test (Specified organism test, BET and sterility test) shall be performed singly while for quantitative test (Total Aerobic Microbial/Viable Count) Triplicate plate preparation shall be done (Three plates shall be prepared and mean of these Three plates shall be reported as final result).

Analysis work sheet and respective GTP shall be provided to the analyst so he/she can be capable to perform the test and record the results after each stage of completion of test. No previous results of product/sample will be shared to the analyst.

Once the analysis gets completed, analyst shall submit the analysis worksheet to head of microbiology for evaluation of results. The analyst shall be considered as validated if the result reported by him / her are within acceptance limits and are within the specifications

Head microbiologist shall evaluate the results and certify that the Microbiologist is qualified as per current version Attachment-I if the results meet the acceptance criteria as mentioned in point No. 6.2.15.

In case the result recorded by analyst do not meet the acceptance criteria. The Micro Head shall evaluate the performance of testing and analysis. The analyst shall be explain his / her deficiency / mistake and trained accordingly. In this case the analyst shall be re-qualified before doing further analysis.

In case of any major analytical error during routine operation, the analyst shall be retrained and re-qualified for respective analytical technique before doing further analysis.

Requalification Criteria: The Microbiologist shall be requalify once in a period of two years.

Acceptance Criteria:

| Microbiological Test | No of Analysis | Acceptance Criteria | |

| Microbial Limit Test of Product | Total Aerobic Microbial Count | Triplicate (Triplicate plates for each test) | Should meet the acceptance criteria as specified in the respective specifications. |

| Specified organism | Single Analysis | ||

| Microbiological analysis of water | Total Aerobic Microbial Count | Triplicate (Triplicate plates for each test)) | |

| Specified organism | Single Analysis | ||

| Sterility Test | Single Analysis | ||

| Bacterial Endotoxin Test (BET) | Single Analysis | ||