SOP ON HANDLING OF BIOHAZARDOUS MATERIAL IN MICROBIOLOGY LAB

PURPOSE: To outline the procedure for Handling Biohazardous Material in the microbiology Lab.

SCOPE: This procedure is applicable for Handling Biohazardous Material in Microbiology Lab.

REFERENCES: In-House & ISO 45001:2018

CROSS-REFERENCE DOCUMENTS

Preparation, Review, Approval, Issuance & Retrieval of Standard Operating Procedures (SOPs)

Change Control Management

Training Program for Employees

Document(S) and Data Control Procedure

Destruction Procedure of Bio-Waste, Used Medi, and Microbial Cultures in Microbiology Lab

Cleaning and Operation of Autoclave in Microbiology Lab

DEFINITIONS

Biohazard – Any biological material (i.e. plants, animals, microorganisms, or their by-products) that may present a potential risk to the health and well-being of humans, animals or the environment.

Hazardous materials are substances that could harm human health or the environment. Hazardous means dangerous, so these materials must be handled the right way.

ABBREVIATIONS

LDPE: Low-density polyethylene

HIRA: Hazard Identification & Risk Assessment

RESPONSIBILITY:

Quality control Department person (Microbiologist): To follow this procedure during the Handling of Biohazardous Material in the Microbiology Lab.

Head-QC/Designee: To ensure the activity as per SOP & implementation of SOP.

Head-QA/Designee: To ensure the implementation & compliance of the defined system

Plant Head: To ensure the implementation of the defined system.

PROCEDURE:

SAFETY/PRECAUTION/EHS

Wear a nose mask and disposable hand gloves before handling biohazardous material.

During loading & unloading of the autoclave always wear a safety heat resistant hand gloves.

Do not keep the glassware rinsed with solvent.

Wash the hands with soap & then rinse with filtered 70% IPA after completing the operation.

Solid/Sharp Material Biohazardous Material:

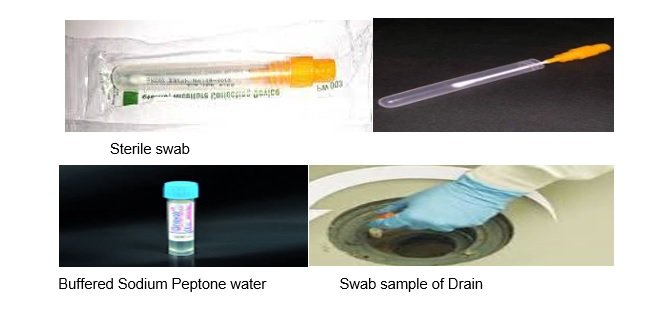

Solid Biohazardous such as culture media plates/ Expiry Material/inoculating loops/BI/ Ampoules/ swabs/Gloves/Contact Plates/Anaerobic Gas Pack.

Wear a nose mask and disposable hand gloves before discarding.

Take the Petri plates add a sufficient amount of validated disinfectant as per the routine schedule in each Petri plate & allow them to stand for 15 minutes for decontamination.

With the help of a spatula scrap out all the solidified media into a LDPE poly bag.

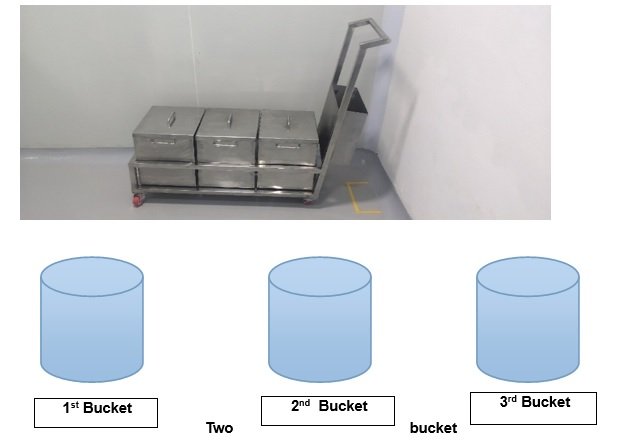

Place the LDPE poly bag in the SS container.

Sterilize the S.S. container in a vertical autoclave with a chemical indicator as per the validated cycle and load pattern (as per the current version SOP.

Operate the vertical autoclave as per current version SOP.

After sterilization collect SS container & run these wastes for the Effluent Treatment Plant with intimation as per SOP.

Liquid Biohazardous Material:

Liquid Biohazardous Such as Culture tubes/flasks/Broth Tubes/Culture suspension Tubes, Media Tubes/Bottles, etc.

Take the Culture Tubes/Broth Tubes/Culture suspension Tubes and place the S.S. test tube rack and flask with a cotton plug.

Sterilize these S.S. racks and flask in a vertical autoclave with a chemical indicator as per the validated cycle and load pattern (as per the current version of SOP.

Operate the vertical autoclave as per the current version of SOP.

After sterilization, take the media from tubes and flasks in an LDPE poly bag and pour a sufficient amount of disinfectant as per schedule.

Run these wastes for the Effluent Treatment Plant with intimation as per the current version of SOP.

Reusable Material or Non-Disposable:

Reusable or Non-Disposable Material such as Equipment, Glassware Bench Tops, etc. contaminated with Biohazardous material & decontaminated by using sa cheduled disinfectant.

Disinfectant appropriate for the bio-hazardous material being used & allow for validated contact time.

Handling of Microbiological Culture:

Microbiological Cultures are handled as per the current version of SOP in the Biosafety Cabinet.

Discarded as per the current version of SOP.

Handling of Spillage of Solid/Liquid Media:

Upon Spillage of the Solid or liquid media, wear surgical gloves & collect solid media & remove excess fluid from the surface with the help of a cotton piece.

Spray filtered 70% IPA & leave it 5 minutes.

Mop the surface twice using a scheduled disinfectant.

Let it dry.

Discard the media with the cotton pieces as per the current version of SOP.

Handling of Waste Product Sample:

After completion of the analysis, all the samples into an LDPE poly bag.

Place the LDPE poly bag in the SS container & run these wastes for the Effluent Treatment Plant with intimation as per SOP.

Hazard Identification & Risk Assessment (HIRA)

Hazard Identification & Risk Assessment (HIRA) shall be prepared as per ISO 45001:2018 standard.