TOOLS FOR QUALITY IMPROVEMENT PART – I

teams of people working together on projects in order to achieve pre-defined quality objectives or Eliminate the root cause(s) of a specific problem is an integral part of ST culture.

To ensure that all these team members are sufficiently equipped to undertake their projects. This requires a basic understanding of a methodology that provides a framework to guide them through working knowledge of the more common data collection, analysis, and interpretation tools.

Quality improvement tools

1. Flow diagram

2. Brainstorming

3. Cause-effect diagram

4. Data collection

5. Graphs and charts

6. Pareto analysis

7. Scatter diagram

8. Histogram

9. Box plot

10. Stratification

1. FLOW DIAGRAM

A flow diagram is a graphic representation of the sequence of steps that we perform to produce an output. The

output may be a physical product, a service, information, or a combination of the three. A flow diagram is used

at the beginning of a project to determine the project scope and boundaries; during the project to provide a

common understanding of the process under investigation; and towards the project end, when it could be used

to make comparisons between current (old) and improved (new) processes. The common symbols used in a flow

diagram are:

1. The activity symbol is a simple rectangle box, which gives a brief description (1-2 words) of the activity in the process.

2. The decision symbol is a diamond-shaped box used to denote any point in the process where a

decision, such as yes/no, up/down, or on/off, must be made, leading to different process

branches.

3. The terminal symbol is a rather flat rectangle with rounded corners, used to denote the

beginning and end of a process or sub-process, often using the words start, begin, or end.

4. Flow lines have an arrow at the end, indicating the process flow to the next activity or step. Besides

the usual downward flow, flow lines can indicate a process loop (going back to an activity) or a

process branch (going to a different set of activities or a sub-process), based on the decision made.

5. The document symbol has the shape of a printout or paper and is used when the activity

described is a printed form.

6. A database symbol is a cylinder and is used when the activity involves access to or retrieval from

a database.

7. The wait symbol is a trapezoid, providing a means to show where normal processing is halted or

suspended to be continued later on.

8. The connector or continuity symbol is a circle with a letter or number in it, used to denote a

breakpoint in the process (most frequently used when the flow diagram reaches the edge of the

paper). An identical symbol is then used to show where the diagram continues.

EXAMPLE

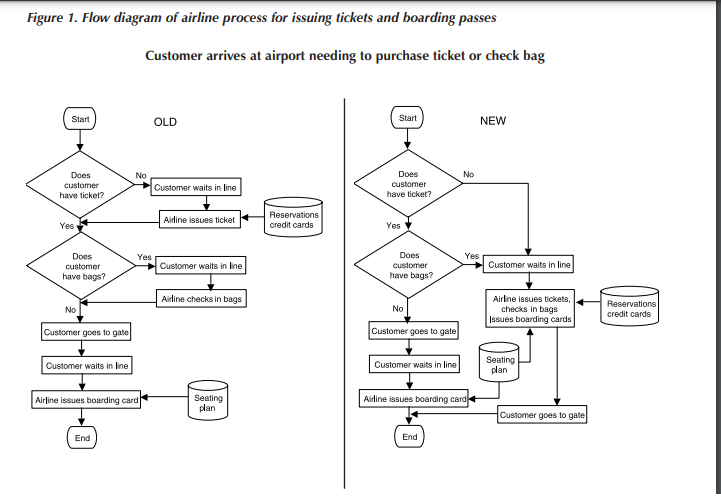

The example below illustrates how flow diagrams can prove useful in both the diagnostic and remedial phases

of a project. The left-hand side of Figure 1 below shows the process that airlines used a few years ago to issue

tickets and boarding passes to passengers without tickets. An examination of the diagram shows that passengers

must stand in two lines, first to purchase the ticket and then at the gate to board. Giving the ticketing agents

access to the seating database is an obvious process improvement that is sure to make passengers happy by

eliminating the need to stand in one of the lines. This improvement is shown on the right side of the figure.

CONSTRUCTION

1. Define how the flow diagram will be used in your project.

2. Decide on the desired outcome of the flow diagram: high level, matrix, or detailed? Construct a high-level

diagram before constructing a detailed diagram.

A high-level flow diagram groups all related activities and decisions in blocks or sub-processes, so that the final diagram is a collection of sub-processes linked together from start to finish.

A matrix (or cross-functional) flow diagram shows the process flow both sequentially and by function. The

diagram is divided into rows or columns, each representing a department, function, or other sub-unit of the

system under study. Each symbol of the flow diagram is placed in the row or column of the unit responsible

for executing it.

3. Define boundaries to the process by identifying the first and last steps.

4. Document each step in the sequence, starting from the first (or last) step. Draw the process accurately and

consistently from the top left to the bottom right edge of the page.

5. When a decision symbol is encountered, select one branch and continue the flow diagram of that branch.

6. When you run into an unfamiliar activity of a sub-process, make a note and continue the flow diagram.

7. Repeat steps 4, 5, and 6 until the last (or first) activity is reached.

8. Go back and flow diagram the other branches of the decision symbols.

9. Review the diagram for any missed decision points or special cases that might cause some work to follow a

different process.

10. Discuss how to fill in the unfamiliar steps or areas of the flow diagram, and verify its accuracy (observe the

process directly, interview experts, show the diagram to line workers, and so on).

11. Interpret the flow diagram, once it is accurate and complete.

INTERPRETATION

The best way to gain an understanding of a process is to walk it through the flow diagram step by step, following

the flow indicated by the arrows. To do this:

1. Examine each decision symbol.

- Is this a checking activity?

- Is this a complete check, or do some type of errors go undetected?

- Is this a redundant check?

2. Examine each rework loop.

- Would we need to perform these activities if we had no failures?

- How long is this rework loop (steps, time lost, resources consumed, ….)?

- Does this rework loop prevent the problem from re-occurring?

3. Examine each activity symbol.

- Is this a redundant activity?

- What is the value of this activity relative to its cost?

- How have we prevented errors in this activity?

4. Examine each document or database symbol.

- Is this necessary?

- How is this kept up to date?

- Is there a single source for this information?

AVOIDING PITFALLS

- When analyzing a problem failure, be sure to document the actual process, and not how the process should

be. - Don’t forget to update the flow diagram as new information is uncovered or as the process is modified.

QUESTIONS

1. When should you use a flow diagram?

2. What is the symbol for an activity? a decision? or a connector?

3. When is a high-level flow diagram best used?

4. How do you proceed when you encounter a branch point when drawing the flow diagram of your process?

5. How can a flow diagram help you better understand a process?

6. What are the common pitfalls to avoid when using a flow diagram as a tool?