PURPOSE OF PERSONAL HYGIENE:

To lay down the procedure for to ensure for Personnel hygiene of all employees working in the company.

SCOPE OF PERSONNEL HYGIENE:

This SOP is applicable for all employees working at Pharmaceuticals Company.

RESPONSIBILITY OF PERSONNEL HYGIENE

- Preparation of SOP: HR Executive /Officer

- Checking and Review of the SOPs: Manager HR

- Approval of Sops: Head of the department / Production Head

- Authorization: Head QA / His Her Designee

ACCOUNTABILITY OF PERSONNEL HYGIENE:

HR head shall be accountable for implementation and Head QA shall be accountable for the compliance of the SOP

PROCEDURE OF PERSONNEL HYGIENE:

- Maintain trimmed, filed, cleaned fingernails without rough edges. No polished fingernails and no artificial nails are permitted in the manufacturing area. Randomly checking of the employees will be conducted on daily basis and recorded.

- Do not wear jewelry including watches

- Arrive to work with clean hair, teeth brushed and bathed

- The person should be properly shaved. The person with a mustache or beard working in the production area should wear a complete beard net.

Smoking, eating, and gum chewing :

- The employees must be instructed during their introduction itself about restrictions on smoking/ chewing Pan/tobacco/gum etc. inside the factory premises.

- Eating and drinking in designated areas

Employees working in the manufacturing area must wash their hands properly before entering the processing area; then gloves shall be put on as required. Hands must always be washed

- Before commencing work

- Before wearing disposable

- Between performing different

- Immediately after using the toilet and returning to work

- After eating or

- After touching face, nose, mouth, skin, hair or other exposed body parts.

- After sneezing, coughing or nose

The person should wear proper clean uniform appropriate to their department.

Wear a cap so as to cover the hair completely.

Wear face mask and gloves in production area to prevent contamination.

Change gloves after touching floor, your face or blowing nose and when torn

Do not carry extra gloves as they may fall unnoticed in equipment.

Change the slippers provided for particular area, as the street slippers bring dust inside.

Inform the respective in charge about wounds or any infectious disease.

Person showing apparent illness or open lesions which may adversely affect the quality of the products, are not allowed to handle starting materials, primary packaging materials and drug products until his condition is no longer judged to be a risk.

Throw the wastage in provided dust bin to keep the respective area clean

Do not cough & Sneeze without protection.

The store used clothes in separate closed container provided in the respective area.

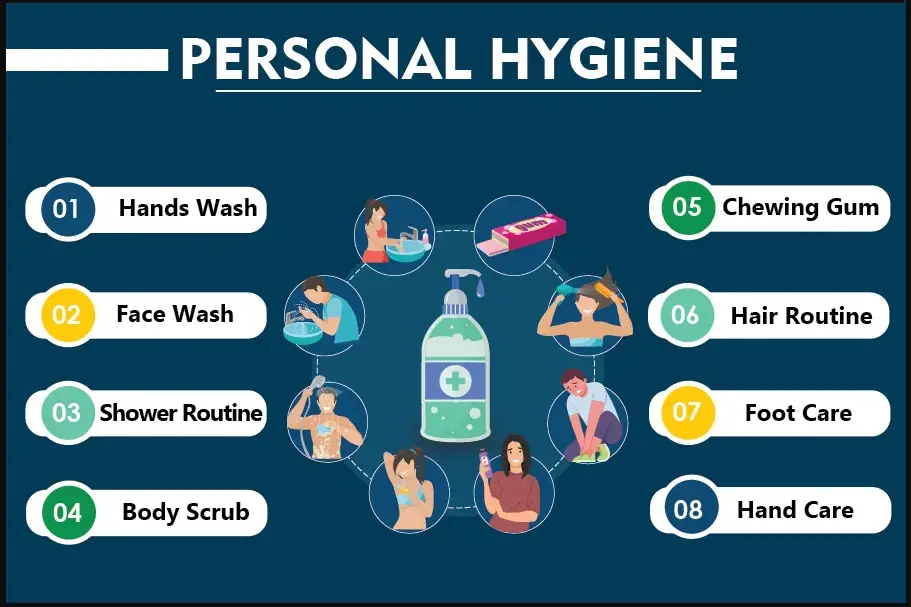

- Toilet hygiene. Wash your hands after you use the restroom. …

- Shower hygiene. …

- Nail hygiene. …

- Teeth hygiene. …

- Sickness hygiene. …

- Hands hygiene.

SOP ON SOP