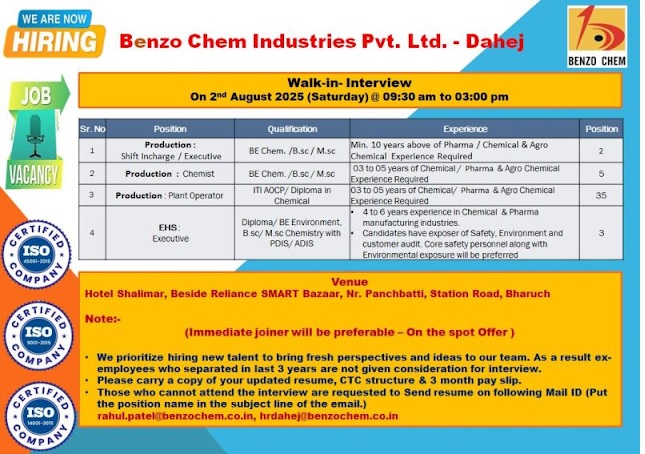

Benzo Chem Industries -Walk In Interviews For Production & EHS On 2nd August 2025 @Bharuch

Production Department

1. Production Shift Incharge / Executive ◾️Qualification: BE Chemical / B.Sc / M.Sc

◾️Experience: Minimum 10 years in Pharma/Chemical/Agro industries ◾️Vacancies: 2

2. Production Chemist

◾️Qualification: BE Chemical / B.Sc / M.Sc

◾️Experience: 3 to 5 years in Chemical/Pharma/Agro industries ◾️Vacancies: 5

3. Production Plant Operator

◾️Qualification: ITI AOCP / Diploma in Chemical

◾️Experience: 3 to 5 years in Chemical/Pharma/Agro industries ◾️Vacancies: 35

4. EHS Executive

◾️Qualification: Diploma / BE Environment / B.Sc / M.Sc with PDIS or ADIS

◾️Experience: 4 to 6 years in Chemical/Pharma manufacturing, safety, environment, audits

◾️Vacancies: 3

Date : 2nd August 2025, Saturday

🕒 Time : 09:30 AM to 03:00 PM

📍 Venue : Hotel Shalimar, Beside Reliance SMART Bazaar, Nr. Panchbatti, Station Road, Bharuch