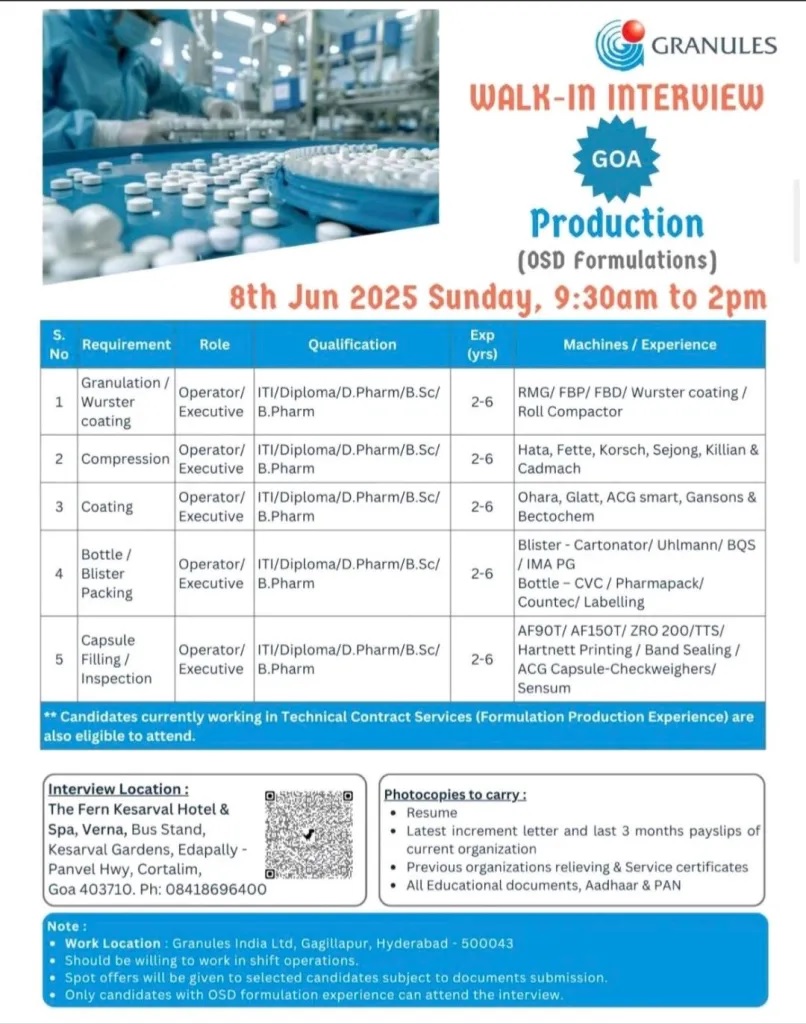

Granules India Ltd-Walk-In Interview-Production Operators/Executives (OSD Formulations) – 8th June 2025,@ Goa

Interview Date: 8th June 2025 (Sunday)

⏰ Time: 9:30 AM to 2:00 PM

📍Venue:The Fern Kesarval Hotel & Spa, Verna, Goa – 403710

📞 Contact: 084186 96400

Granules India is hiring for multiple roles in Granulation, Compression, Coating, Packing, and Capsule Filling. Here’s a quick overview:

1) Department: Granulation / Wurster Coating

Role: Operator/Executive

Qualification: ITI/Diploma/D.Pharm/B.Sc/B.Pharm

Experience: 2-6

Machines/Expertise Required: RMG, FBP, FBD, Wurster Coating, Roll Compactor

2) Department: Compression

Role: Operator/Executive

Qualification: ITI/Diploma/D.Pharm/B.Sc/B.Pharm

Experience: 2-6

Machines/Expertise Required:

Hata, Fette, Korsch, Sejong, Killian, Cadmach

3) Department: Coating

Role: Operator/Executive

Qualification: ITI/Diploma/D.Pharm/B.Sc/B.Pharm

Experience: 2-6

Machines/Expertise Required: Ohara, Glatt, ACG Smart, Gansons, Beetochem

4) Department: Bottle/Blister Packing

Role: Operator/Executive

Qualification: ITI/Diploma/D.Pharm/B.Sc/B.Pharm

Experience: 2-6

Machines/Expertise Required: Blister (Cartonator, Uhlmann, BQS, IMA PG), Bottle (CVC, Pharmapack)

5) Department: Capsule Filling/Inspection

Role: Operator/Executive

Qualification: ITI/Diploma/D.Pharm/B.Sc/B.Pharm

Experience: 2-6

Machines/Expertise Required:

AF90T, AF150T, ZRO 200, TTS, ACG Capsule Checkweighers, Sensum

✅ Eligibility:

Education: ITI, Diploma, D.Pharm, B.Sc, B.Pharm

Experience: 2-6 years in OSD Formulation Production

Note: Candidates from Technical Contract Services with relevant experience can also apply!

📌 Documents Required

Candidates must bring the following documents:

•Updated Resume

•Latest Increment Letter + Last 3 Months’ Payslips

•Relieving & Service Certificates (Previous Companies)

•All Educational Certificates

•Aadhaar Card & PAN Card

Work Location:Granules India Ltd., Gagillapur, Hyderabad – 500043

•Shift Work: Must be willing to work in rotational shifts

•Spot Offers: Selected candidates may receive on-the-spot job offers upon document verification

•Only OSD Experience Candidates: Only those with OSD formulation experience should attend