Granules India-Walk in Drive for D.Pharm, B.Pharm, M.Pharm in Production, Quality Control, IPQA on 25th May 2025,

Granules India is a vertically integrated, high-growth pharmaceutical company with 38 years of proven performance and increasing performance and increasing presence across the world. Headquartered in Hyderabad, India, Granules offers collaborative and strategic partnership to global pharmaceutical leaders by producing best quality API, PFI and FD through manufacturing excellence, process innovation and regulatory expertise.

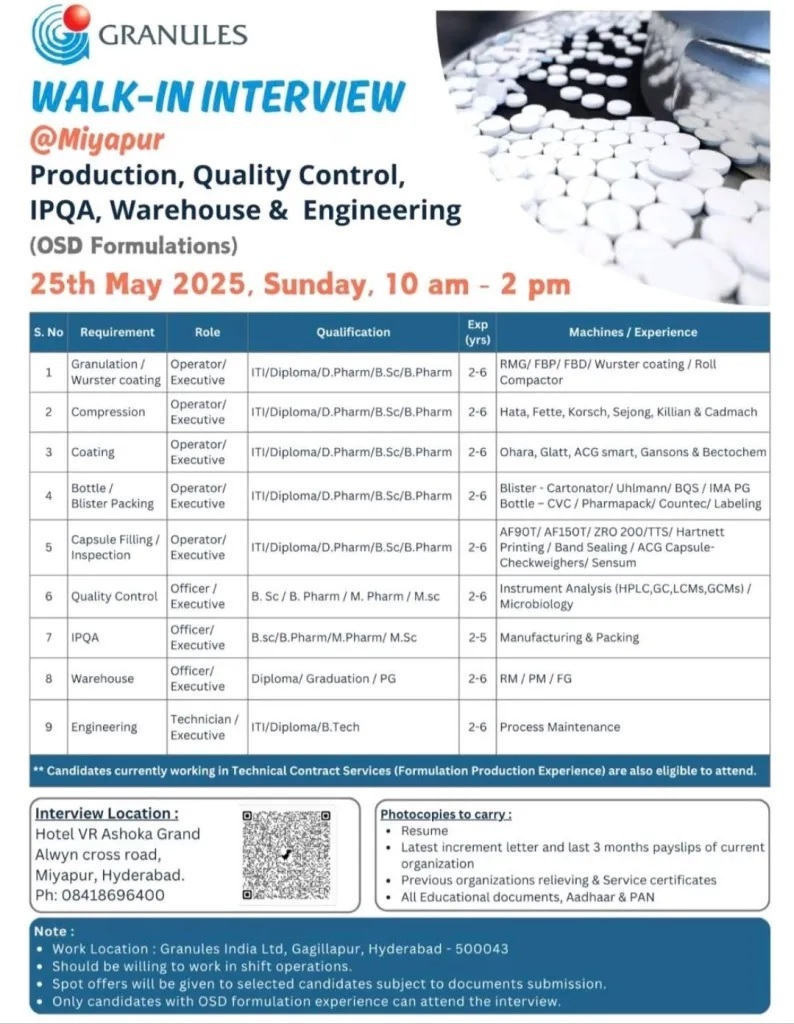

WALK-IN INTERVIEW at Miyapur Production, Quality Control, IPQA, Warehouse & Engineering (OSD Formulations)

Granulation / Wurster coating

Post : Operator / Executive

Qualification : ITI/Diploma/D.Pharm/B.Sc/B.Pharm

Experience : 2-6

Machines / Experience : RMG/ FBP/ FBD/ Wurster coating / Roll Compactor

Compression

Post : Operator / Executive

Qualification : ITI/Diploma/D.Pharm/B.Sc/B.Pharm

Experience : 2-6

Machines / Experience : Hata, Fette, Korsch, Sejong, Killian & Cadmach

Coating

Post : Operator / Executive

Qualification : ITI/Diploma/D.Pharm/B.Sc/B.Pharm

Experience : 2-6

Machines / Experience : Ohara, Glatt, ACG smart, Gansons & Bectochem

Bottle / Blister Packing

Post : Operator / Executive

Qualification : ITI/Diploma/D.Pharm/B.Sc/B.Pharm

Experience : 2-6

Blister – Cartonator/ Uhlmann/ BQS / IMA PG Bottle – CVC / Pharmapack/ Countec/ Labeling

Capsule Filling/ Inspection

Post : Operator / Executive

Qualification : ITI/Diploma/D.Pharm/B.Sc/B.Pharm

Experience : 2-6

Machines / Experience : AF90T/ AF150T/ ZRO 200/TTS/ Hartnett Printing / Band Sealing / ACG Capsule- Checkweighers/ Sensum

Quality Control

Post : Officer/ Executive

Qualification : B. Sc / B. Pharm / M. Pharm / M.sc

Experience : 2-6

Machines / Experience : Instrument Analysis (HPLC,GC,LCMs,GCMs) / Microbiology

IPQA

Post : Officer / Executive

Qualification : B.sc/B.Pharm/M.Pharm/ M.Sc

Experience : 2-5

Machines / Experience : Manufacturing Packing

Warehouse

Post : Officer/ Executive

Qualification : Diploma/ Graduation / PG

Experience : 2-6

Machines / Experience : RM/PM/FG

Candidates currently working in Technical Contract Services (Formulation Production Experience) are also eligible to attend.

Note :

• Work Location : Granules India Ltd, Gagillapur, Hyderabad – 500043

• Should be willing to work in shift operations.

• Spot offers will be given to selected candidates subject to documents submission.

• Only candidates with OSD formulation experience can attend the interview.

Walk in Interview

Date & Time : 25th May 2025, Sunday, 10 am – 2 pm

Interview Location : Hotel VR Ashoka Grand Alwyn cross road, Miyapur, Hyderabad.

Photocopies to carry: Resume Latest increment letter and last 3 months payslips of current organization Previous organizations relieving & Service certificates All Educational documents, Aadhaar & PAN