Objective:

To lay down the procedure for Viable Particulate Monitoring of Drain Points – Sterile Product Manufacturing Facility

Scope:

This SOP is applicable for Viable Particle Monitoring of Drain Points – Sterile Product Manufacturing Facility

Responsibility:

Officer or above of Microbiology Laboratory.

Head – Microbiology section / Nominee.

Accountability:

Head – Quality Control / Nominee.

Head – Quality Assurance.

Procedure:

Viable particle monitoring of drain points in sterile product manufacturing facility shall be performed by microbiologist.

Perform the viable particle monitoring drain points in sterile product manufacturing facility by surface swabbing method.

Preparation of plates and other accessories

Prepare and sterilize required number of SCDA (Soya bean Casein Digest agar Medium plates and pre-incubate as per SOP on Preparation of sterile media.

Sterilize required number of tubes containing 10 ml of saline and a swab and place them in test tube stand.

Sterilize required number of SS carriers.

Place the test tube stands in the carriers.

Carry SS carriers to the facility to be monitored by following plant entry procedure.

Take out the items from the SS bin and start the monitoring using the procedures mentioned below.

Swab method:

Aseptically open the test tube containing swab and take out the sterile swab partially, press the swab to the internal walls of the tube gently to remove excess saline and take out completely.

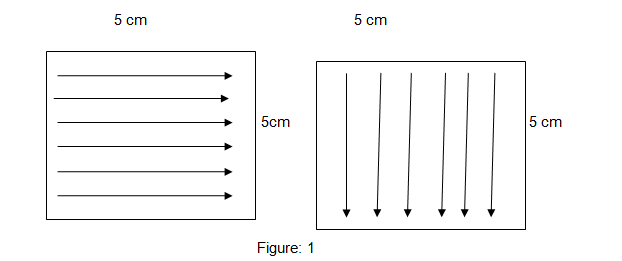

Swab about 25 cm2 area in the direction specified in Figure: 1

Place the swab in the saline containing tube and close.

After completion of test label each plate on bottom side with location code, shift and date.

Perform the sampling in all the locations using same procedure.

Place all the swab tubes and place the stands in SS carriers.

After complete sampling, bring all the medium swab tube carriers to microbiology laboratory for analysis.

Perform the testing of swabs, in MLT testing room.

First, vortex the solution (saline) contained in each tube along with swab and filter through a sterile 0.45 µm membrane filter and rinse the membrane filter with 100 ml X 3 of 0.1% peptone water and place the membrane filter on pre-incubated SCDA medium plate. Use different filter holder for each swab.

Incubate the plates at 20-25 0C for 72 hours and at 30-35 0C for further 48 hours. Observe the plates after 72 hours and after further 48 hours and record the results.

Frequency

Once in a Month

Acceptable levels

Verify that the monitoring results are with in the acceptable levels mentioned in the particular annexure.

List of Annexure :

| S. No. | Annexure Title | Annexure Number |

| 01 | Report of Viable Particles Monitoring Drain points |

I |

References (if any).

Not Applicable

Reason for Revision

New SOPs

Abbreviations;

QC: Quality Control

SOP: Standard Operating Procedure

End of SOP

Annexure – I

Report of Viable Particles Monitoring Drain points

| Facility | Sterile Product

Manufacturing |

Areas | Adjacent to Sterile filling Areas | |

| Medium used | A.R.No | |||

| Medium Lot.No | Sample Size | 25 cm2 | ||

| Time of Test | From | Tested on | ||

| To | Reported on | |||

| Incubation Temperature | Period | Incubator I.D.No. | ||

| 20-25°C | From: To: | |||

| 30-35°C | From: To: | |||

| Area | Location

Code for plate

|

Total Viable Count(CFU’s/Location) | ||||

| After 72 hrs | After further 48 hrs | Total viable count after 5 Days

|

||||

| Bacterial | Fungal | Bacterial | Fungal | |||

| Garment Washing Room(Drain Point-1) | AS-DP01 | |||||

| Washing and Sterilization Room Drain Point-II) | AS-DP02 | |||||

| Bung Processor cum Sterilizer

(Drain Point-III) |

AS-DP03 | |||||

| Equipment washing and Sterilization room (Drain Point III) | AS-DP04 | |||||

| Observation done by | ||||||

| Date of observation | ||||||

Legend: AS-DP: Adjacent to sterile Filling Areas-Drain Point

Interpretation: The viable particle counts of drain points tested by swab test are within /not within the acceptable levels.

Acceptable level of Total Viable Count (CFU/Location):100 CFU’s

Comments:_________________________________________________________________

Performed By/Date Checked By/Date: Reviewed By/Date: