What is Pre-dispatch inspection?

Pre-dispatch inspection is a step taken by manufacturers to inspect finished products before dispatch of the finished product for sale and distribution in the market for the supply of medicine to user points.

The purpose of Pre-dispatch inspection is:

Check the quantity and quality of the finished product.

Check the product for defects.

Ensure that products meet product requirements in destination markets.

Publish import and invoicing reports.

Steps to the Pre-dispatch Inspection Procedure

Step 1: On-site inspection during Pre-dispatch inspection

Pre-dispatch inspection is carried out on-site at the factory or production facility. If inspectors suspect that products may contain any defect, they may recommend additional checks and verification of those products.

Step 2. Confirm the quantity during Pre-dispatch inspection.

Inspectors count shipping boxes to ensure correct quantities. Additionally, this step ensures that the correct number of products and boxes are sent to the correct destination. In this way, a dispatch inspection check can be agreed between the buyer, and supplier to initiate payment under the letter of credit.

Packaging is also checked to ensure that the correct packaging material is used and that the correct packaging label is included to ensure safe transport.

Step 3. Random selection during Pre-dispatch inspection

Our professional pre-dispatch inspection services use the internationally recognized statistical sampling procedure.

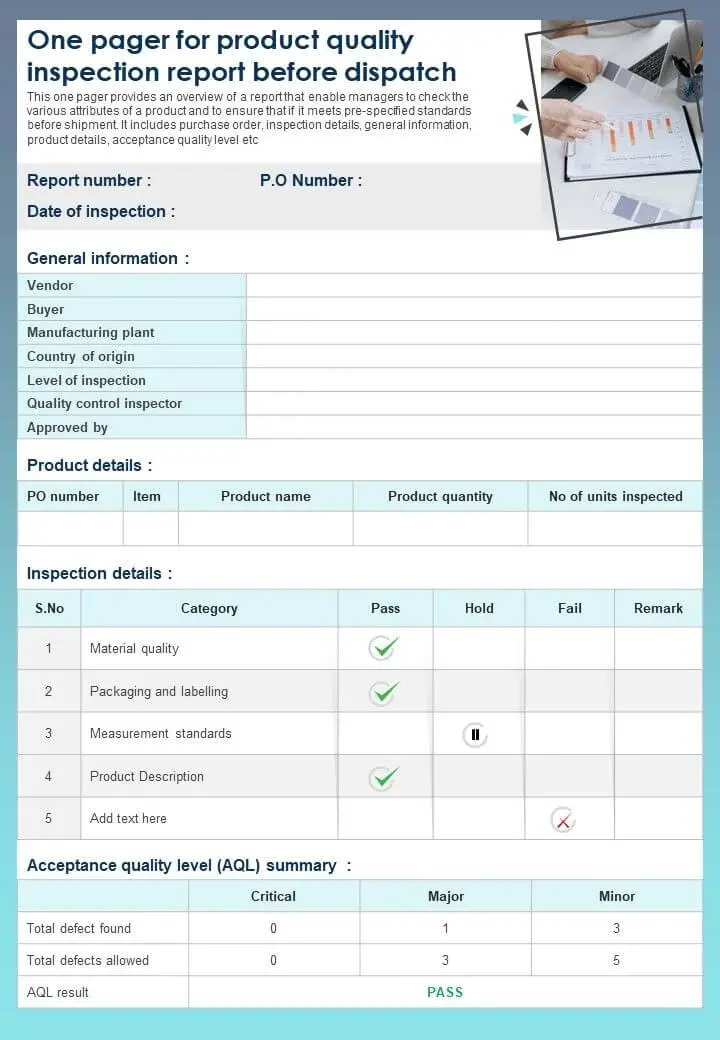

The number of defects allowed in a lot before it is rejected is determined by the acceptable quality limit (AQL). AQLs vary depending on the type of product being assessed, but the goal is to provide a balanced and unbiased opinion.

Step 4: Check Appearance and Finish during Pre-dispatch inspection

The first thing the inspector checks on a randomly selected product is to check the overall workmanship of the finished product and the presence of immediately visible defects.

Defects are classified as minor, major or critical based on predefined acceptable tolerance levels that are typically agreed upon between manufacturers and suppliers during product development.

Step 5: Check suitability during Pre-dispatch inspection

Quality inspectors check product dimensions, materials and design, weight, color, markings, and labels. If pre-dispatch inspection is carried out on clothing, the inspector will check that the correct size has been assigned to the shipment and that the size matches the production dimensions and label.

Quality Management

The Procedure of Pre-dispatch Inspection

QA Officer/Executive shall inspect during/after the packing process of finished products.

Check all the parameters as below mentioned in the ‘Pre-dispatch Inspection Report’.

Select under root n+1 numbers of corrugated boxes (n= total number of corrugated boxes) and sample from corrugated boxes as below:

-

- First corrugated box.

- Last/Loose corrugated box.

- Randomly select a corrugated box.

Select 20% of unit/multi cartons randomly for each selected corrugated box.

Select all core units from each selected unit carton. Refer to the below example:

| Sr. No. | Packing profile | No. of units to be sampled and inspected. | |

| Unit | Nos. | ||

| 1 | Total corrugated box per transfer/batch | 100 |

Under root n+1= 11 C. Box n: total number of corrugated boxes |

| 2 | Total multi cartons per corrugated boxes | 20 | Total 4 multi cartons randomly from each selected box (20% of 20 multi cartons = 4) |

| 3 | Total unit cartons per multi cartons | 10 | Total 2-unit cartons randomly from each selected multi-carton (20% of 20 multi cartons = 2) |

| 4 | Total core units (e.g. blister/strip/bottles/Sachet) per unit carton | 10 | All core units i.e. 10 nos. |

Inspect each selected corrugated box, multi-carton, unit carton, and core unit for the parameters.

If any parameter mentioned below the checklist is not applicable, write ‘N/A’ in the ‘Observation’ column.

If no defect is observed during inspection, follow the procedure as mentioned below:

Write ‘ok or not ok & NA’ in the ‘Observation’ column below mentioned checklist if observed non-conformity (not ok) then provide immediate correction, corrective action & preventive action.

The store head shall ensure that goods are dispatched only after receiving the ‘Finish Good Release note’ as per respective SOP.

If any defect is observed during the inspection, follow the procedure as mentioned below:

Record the same in ‘Observation’ and immediately inform the same to the production head as well as QA head.

Carry out re-sampling and inspection, Record the observation of re-sampling units, and give remarks therein accordingly.

Fill deviation form and get it approved by QA. On approval of deviation, the QA Head shall inform to production head for corrective and preventive actions.

Pre-dispatch inspection checklist for Syrup/Suspension/Dry powder

- Printed Cello Tape & BOPP Tape (with instruction or without instructions used As per Specification (Tick appropriate option used). Sealing of shipper with BOPP Tape done

- Shipper label should be used as per given specification only & Shipper Overprinting Quality / Label Details (Quantity per shipper mentioned in brackets) Shipper label placed centrally and covered with transparent cello tape.

- Shipper Fill Value/ Missing Units. Physical condition of packed shipper. Packed units in shippers as per PPS

- Container Label / Outer Carton Overprinting

- Packed Qty. inside Inner Carton/Outer Carton/Shrink as per PPS.

- Batch coding on labels and cartons / Inkjet or image printing quality on Sachet

- Missing Leaflet/Measuring Cup/Dropper in Carton

- Sealing quality Leakages / Dented bottles

- Bottle labeling Quality (Cross/Torn/Wrinkle/missed)

- Foreign Particles

- Sachet sealing quality / any leakage.

- Cutting defects of ROPP caps/improper fittings

- Scratch/ uncleaned bottles

- Half-fill bottles/ less volume bottles/ overflow bottles

- The shipper Number / Weight is mentioned manually with a marker separately (After packing) on the left-hand top corner of the shipper on the same side where the label is pasted After packing.

- Loose Shipper Sealed with plain Red Tape Only/ Quantity of materials.

- Other Defects

- Total Defect

- Total Replaced Units

Pre-dispatch inspection checklist for Tablet

- Printed Cello Tape & BOPP Tape (with instruction or without instructions) used As per Specification (Tick appropriate option used). Sealing of shipper with BOPP Tape done

- Shipper label should be used as per given specification only & Shipper Overprinting Quality / Label Details (Quantity per shipper mentioned in brackets)

- The shipper label is placed centrally and covered with transparent cello tape.

- Shipper Fill Value/ Missing Units

- Physical condition of packed shipper.

- Packed units in shippers as per PPS

- Inner / Container label / Outer Carton Overprinting

- Packed Qty. inside Inner Carton/Outer Carton/Shrink as per PPS.

- Cracked tablet/ Half tablet / Capping / Picking /Sticking / Lamination

- Cut pockets / Punctured Strips/ Blisters/ALU-ALU Blisters.

- Deformed / Dented / locking defect /split /Punched end.

- Blister/ Strip//ALU-ALU Blisters. overprinting/ smudging/ embossing

- Batch coding details on strip / cartons and shippers

- Empty/Torn Pocket of blister/ strip

- Missing units/extra units of Blister or Strip

- Black Spot/Black Particle/ Powder in Pocket

- Blister/Strip improper knurling

- Shipper Number / Weight mentioned manually with marker separately (After packing) on left hand top corner of the shipper on the same side where label is pasted After packing.

- Loose Shipper Sealed with plain Red Tape Only/ Quantity of materials.

- Other Defects

- Total Defect

- Total Replaced Units

Pre-dispatch inspection check list for SVP

- As per Specification, sealing of shipper with plain BOPP Tape done.

- Shipper label should be used as per given specification only (Company Name) & Shipper Overprinting Quality / Label Details (Quantity per shipper mention in brackets)

- Shipper label placed centrally and covered with transparent cello tape.

- Shipper Fill Value/ Missing Units

- Physical condition of packed shipper.

- Packed units in shippers as per PPS

- Ampoules label should be in correct direction & affixed firmly.

- Packed Qty. inside Inner Carton/Outer Carton/Shrink as per PPS.

- Black Spot/Black Particle/ Foreign Particle

- Ampoules free from rough surface, extra plastic, deep line & should not be leaked.

- Shipper Number / Weight mentioned manually with marker separately (After packing) on left hand top corner of the shipper on the same side where label is pasted After packing.

- Loose Shipper Sealed with plain Red Tape Only/ Quantity of materials.

- Other Defects

- Total Defect

- Total Replaced Units